Last edited by  lilal

lilal

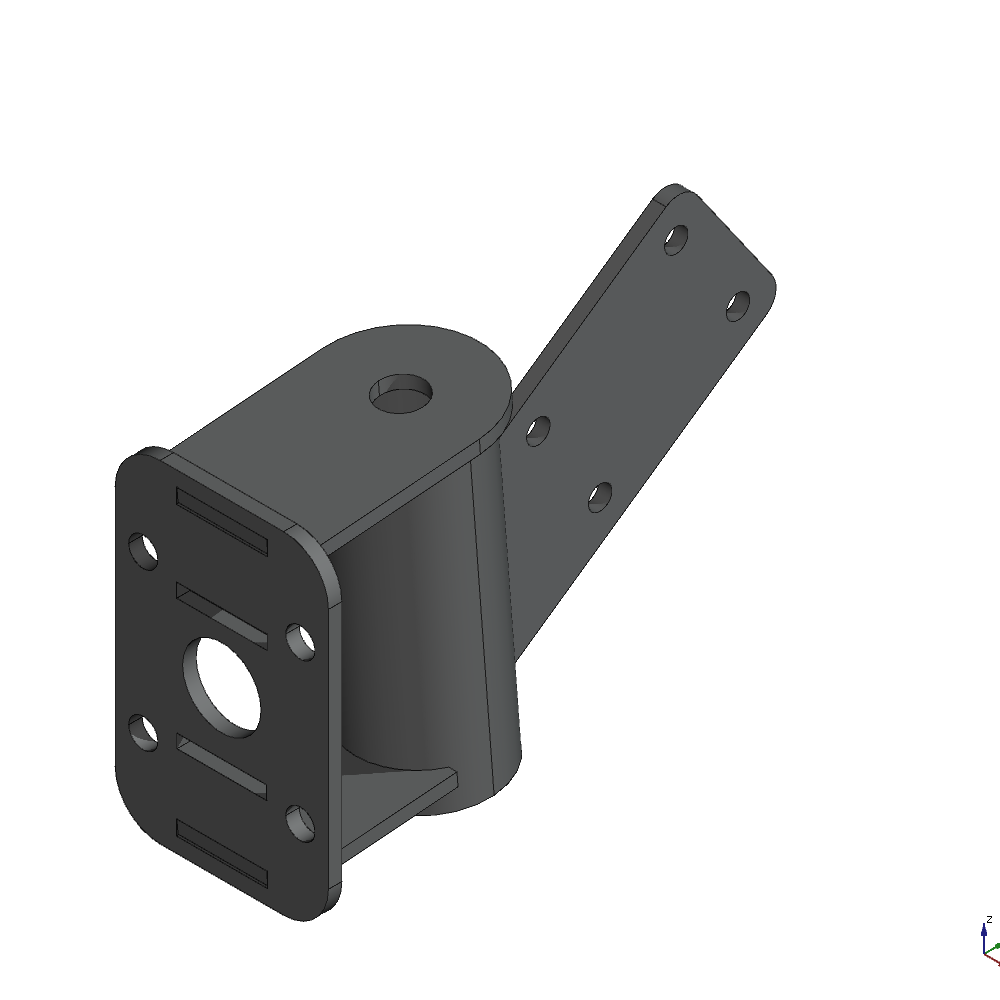

Overview

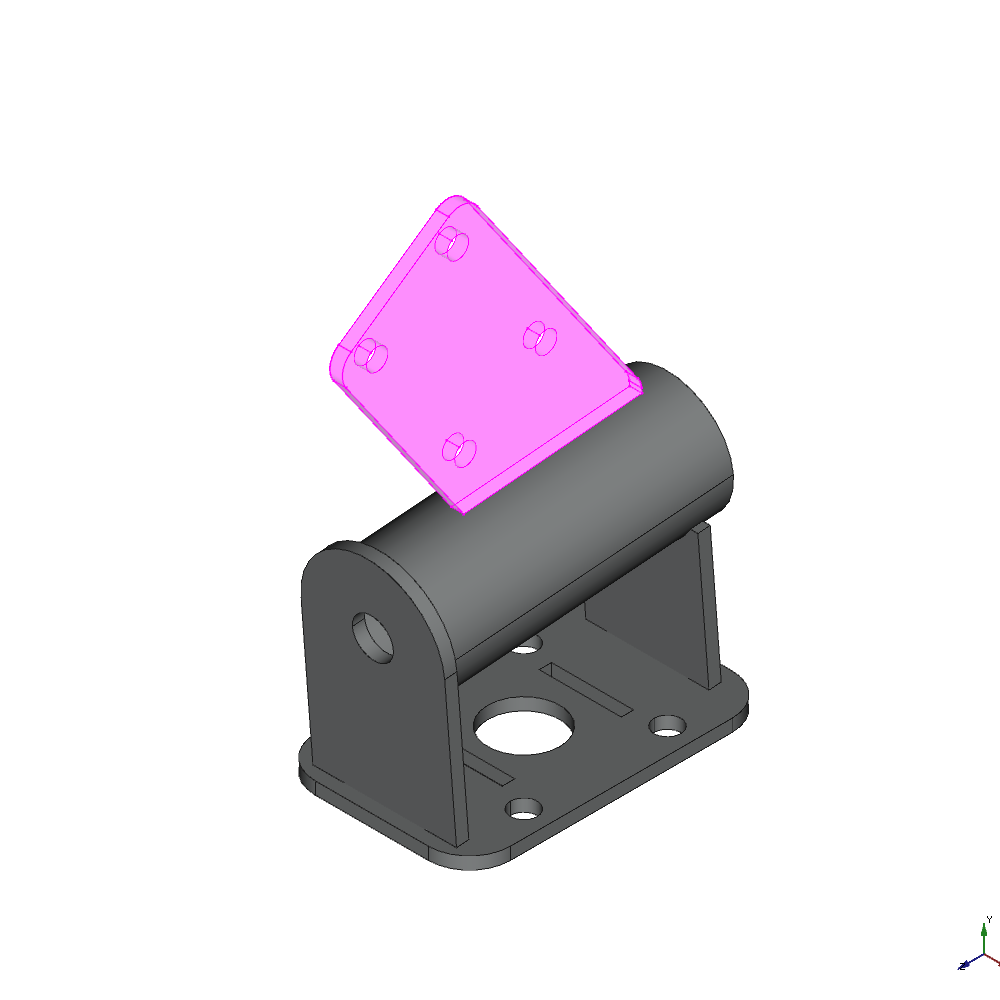

![SubAssembly.Nacelle]()

Materials needed

| No. |

Component |

Units |

Category |

Product Name |

| 1 |

Bearing Mounting Plate |

1 |

Laser |

Steel S235 Or S355, 6 Mm Thick, No Surface Treatment |

| 2 |

Upper Spacer |

1 |

Laser |

Steel S235 Or S355, 6 Mm Thick, No Surface Treatment |

| 3 |

Lower Spacer |

1 |

Laser |

Steel S235 Or S355, 6 Mm Thick, No Surface Treatment |

| 4 |

Yaw Pipe |

1 |

Catalogue |

Cylindric Pipe, Steel, No Surface Treatment, 60,3 X 3,65 X 140 Mm |

| 5 |

Cable Gland |

1 |

Catalogue |

Tbd |

| 6 |

Wind Vane Socket |

1 |

Laser |

Steel S235 Or S355, 6 Mm Thick, No Surface Treatment |

Tools needed

| No. |

Name |

|

| 1 |

Welder |

|

| 2 |

Welding equipment |

Gloves, Helmet, Welding Magnets |

| 3 |

Square |

|

| 4 |

Angle Grinder |

|

| 5 |

Safety Glasses |

|

| 6 |

Level |

|

| 7 |

Meter |

|

Build

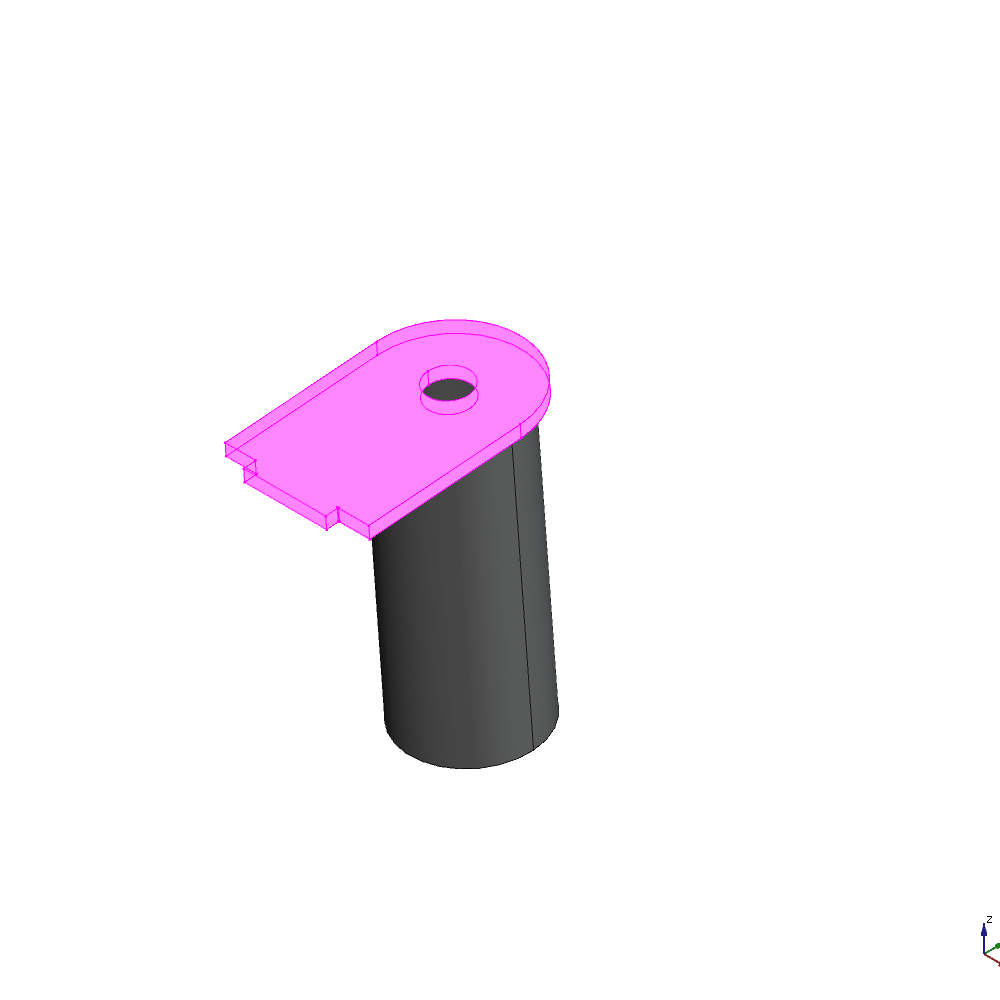

1.Place Upper Spacer on to the Yaw Pipe

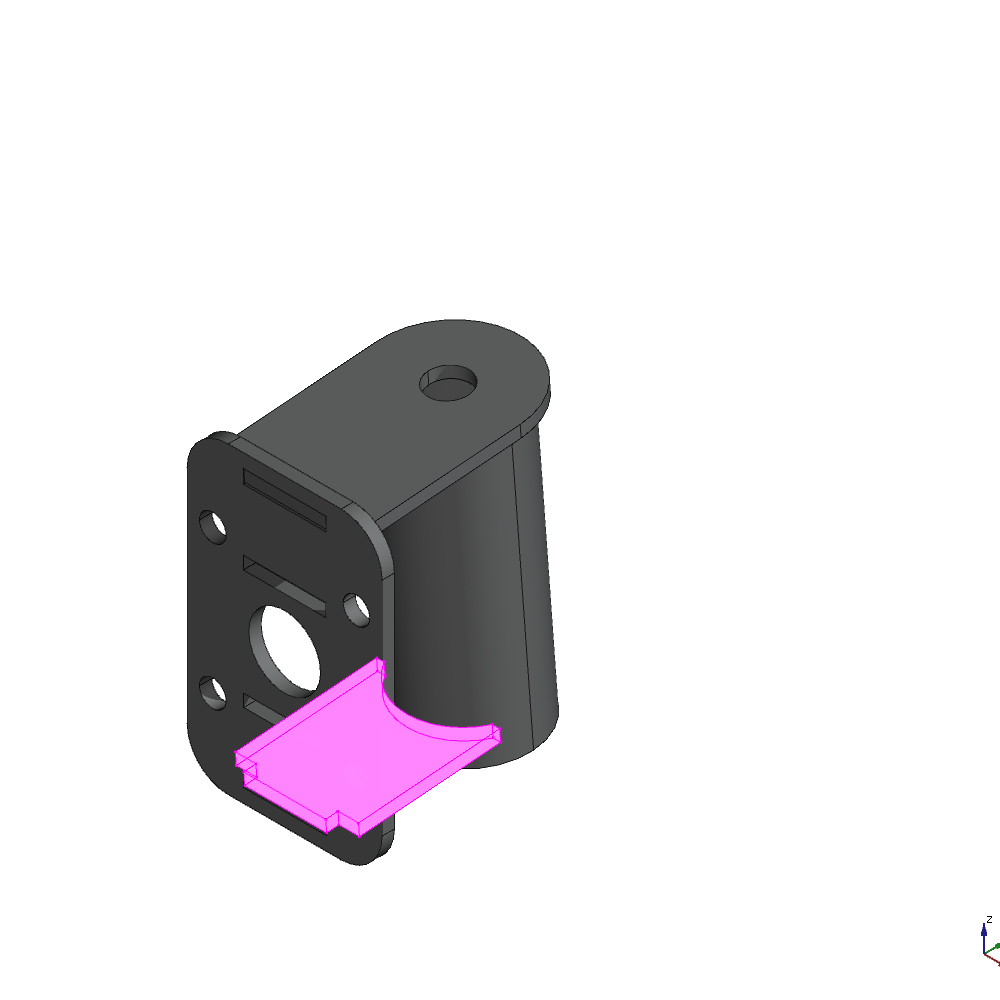

![SubAssembly.Nacelle_1]()

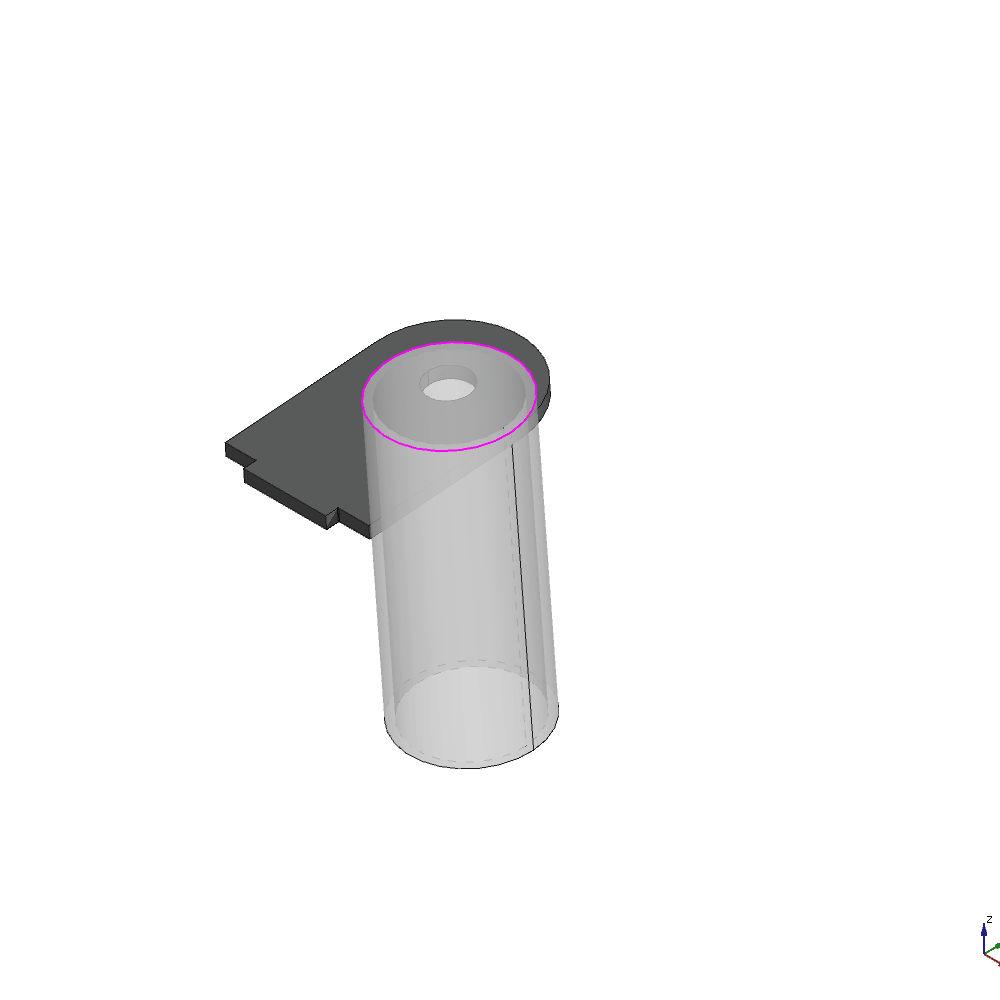

2.Spot-weld Upper Spacer on to the Yaw Pipe

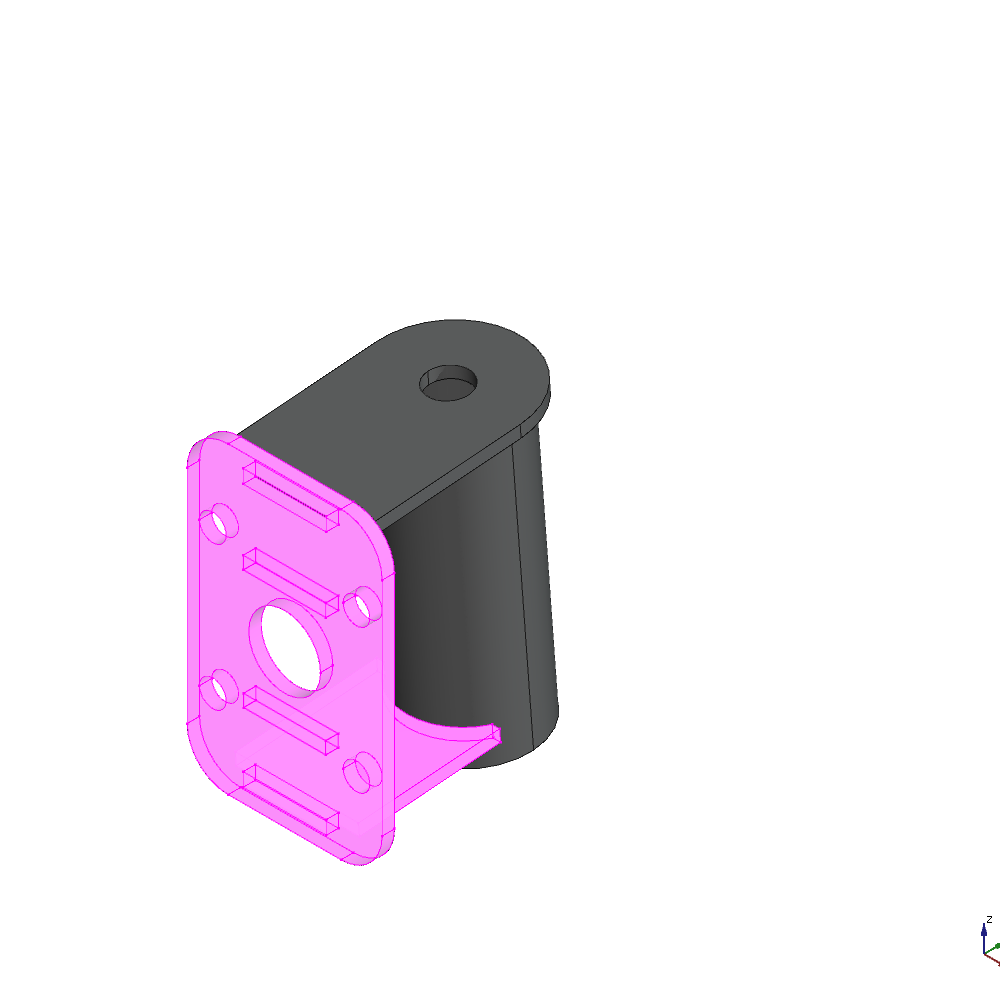

![SubAssembly.Nacelle_2]()

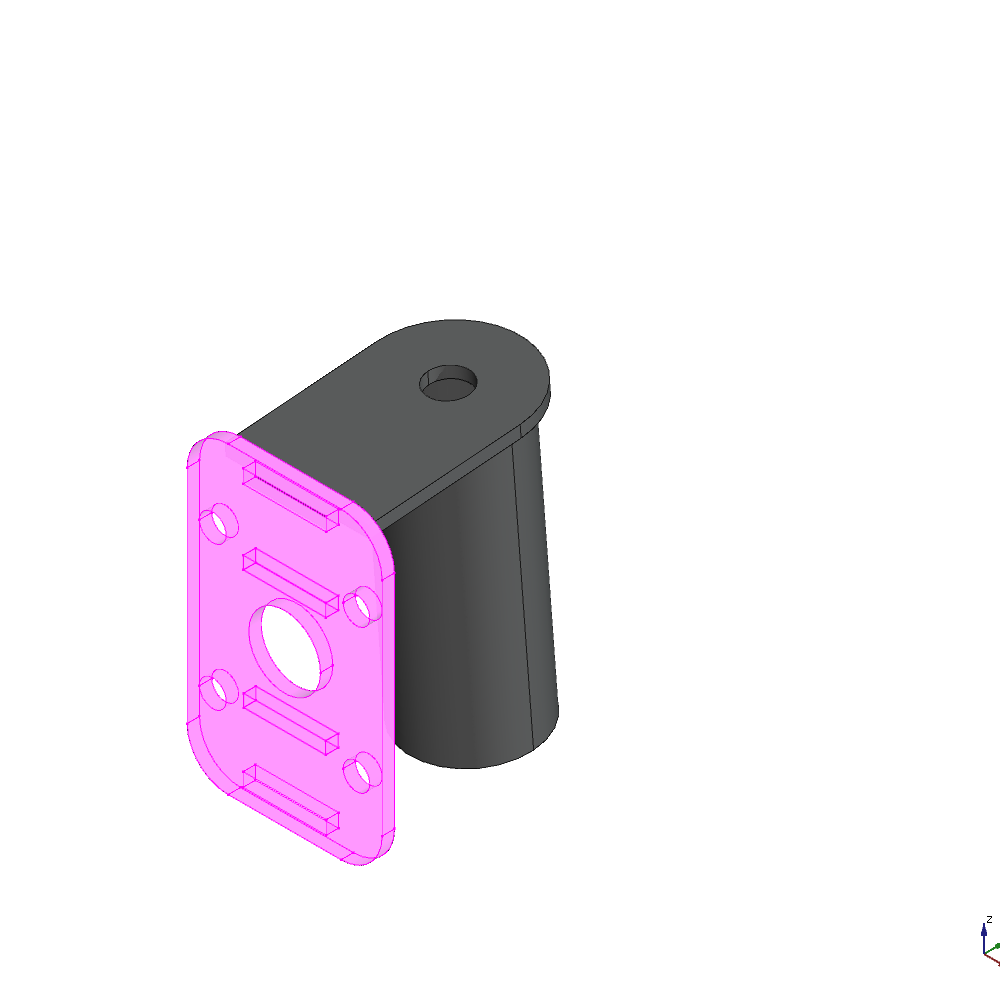

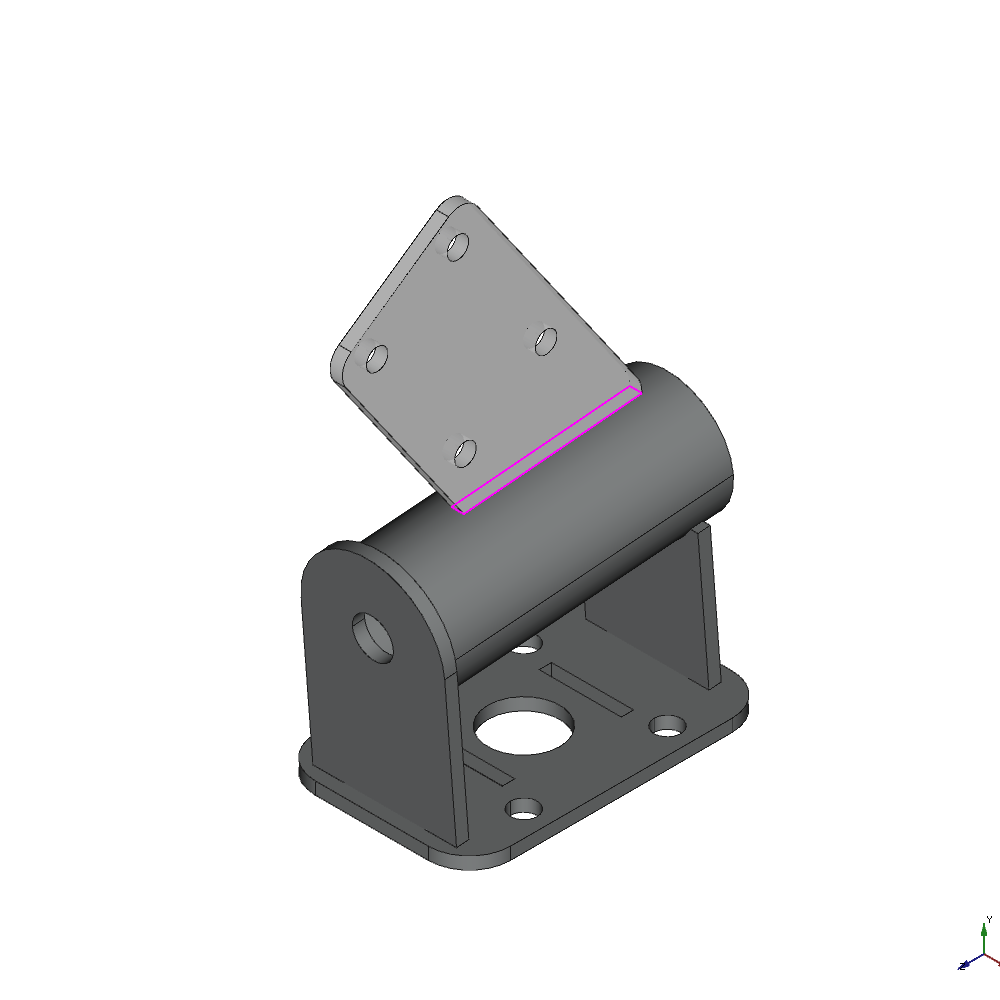

3.Place and Bearing Mounting Plate and Lower Spacer

![SubAssembly.Nacelle_3]()

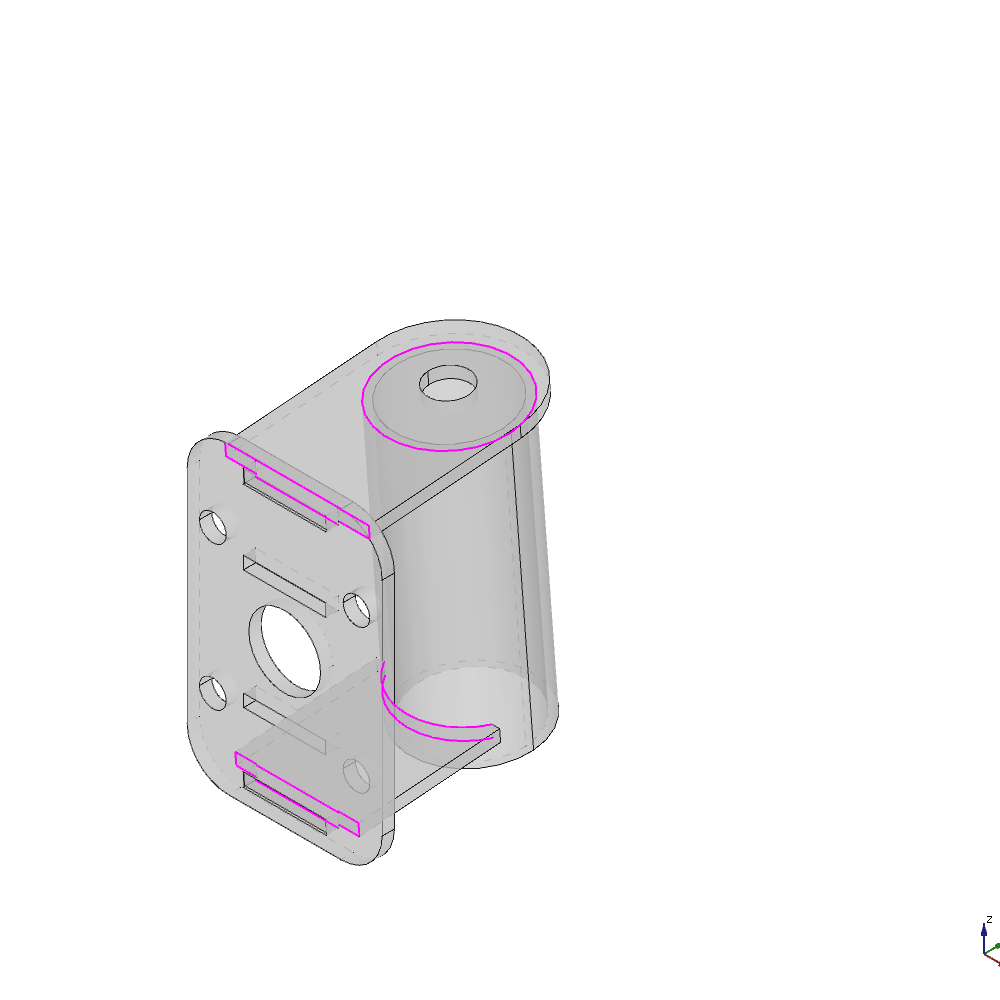

![SubAssembly.Nacelle_4]()

4.Spot-weld Bearing Mounting Plate and Lower Spacer

![SubAssembly.Nacelle_5]()

5.Weld Bearing Mounting Plate and Lower Spacer

![SubAssembly.Nacelle_6]()

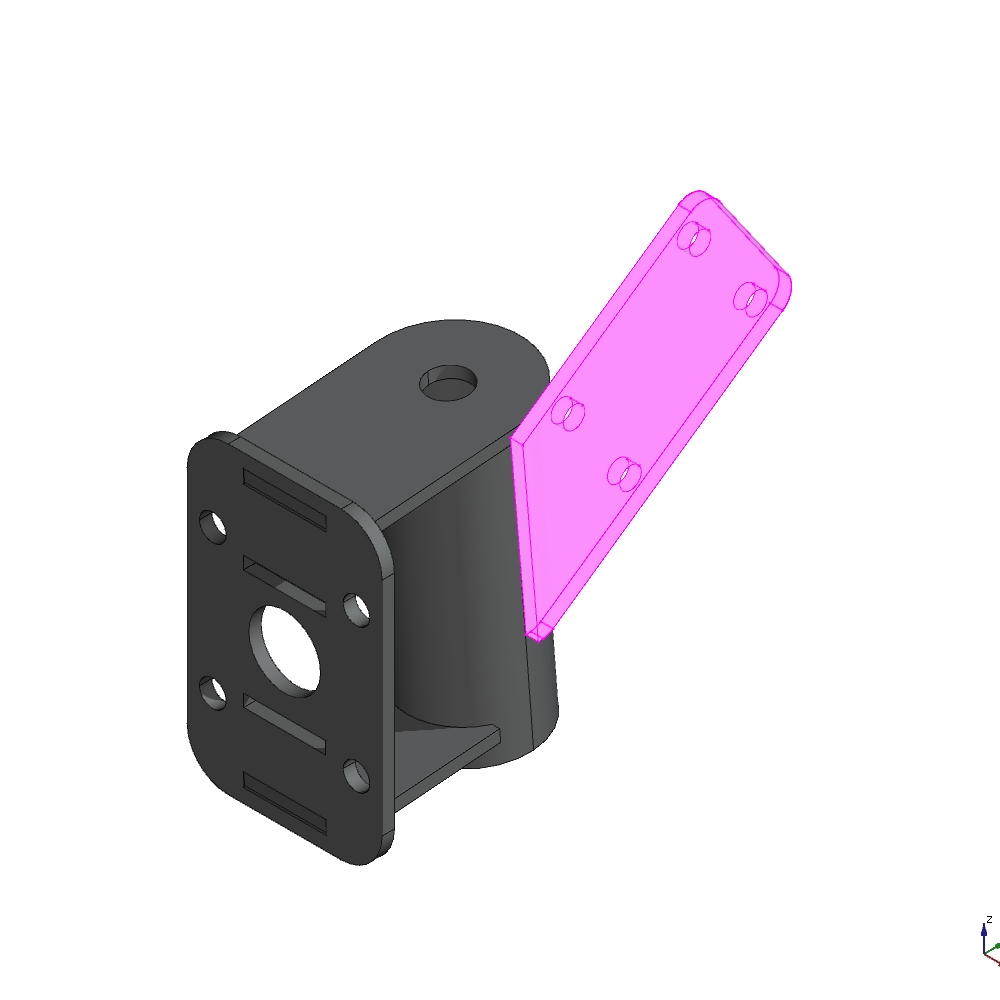

6.Place the Wind Vane Socket

15mm distance

![SubAssembly.Nacelle_7]()

![SubAssembly.Nacelle_8]()

7.Weld the Wind Vane Socket

![SubAssembly.Nacelle_9]()

8.Paint the Nacelle

![SubAssembly.Nacelle_10]()

9.Mount the Cable Gland

![SubAssembly.Nacelle_11]()

![SubAssembly.Nacelle_12]()