Overview

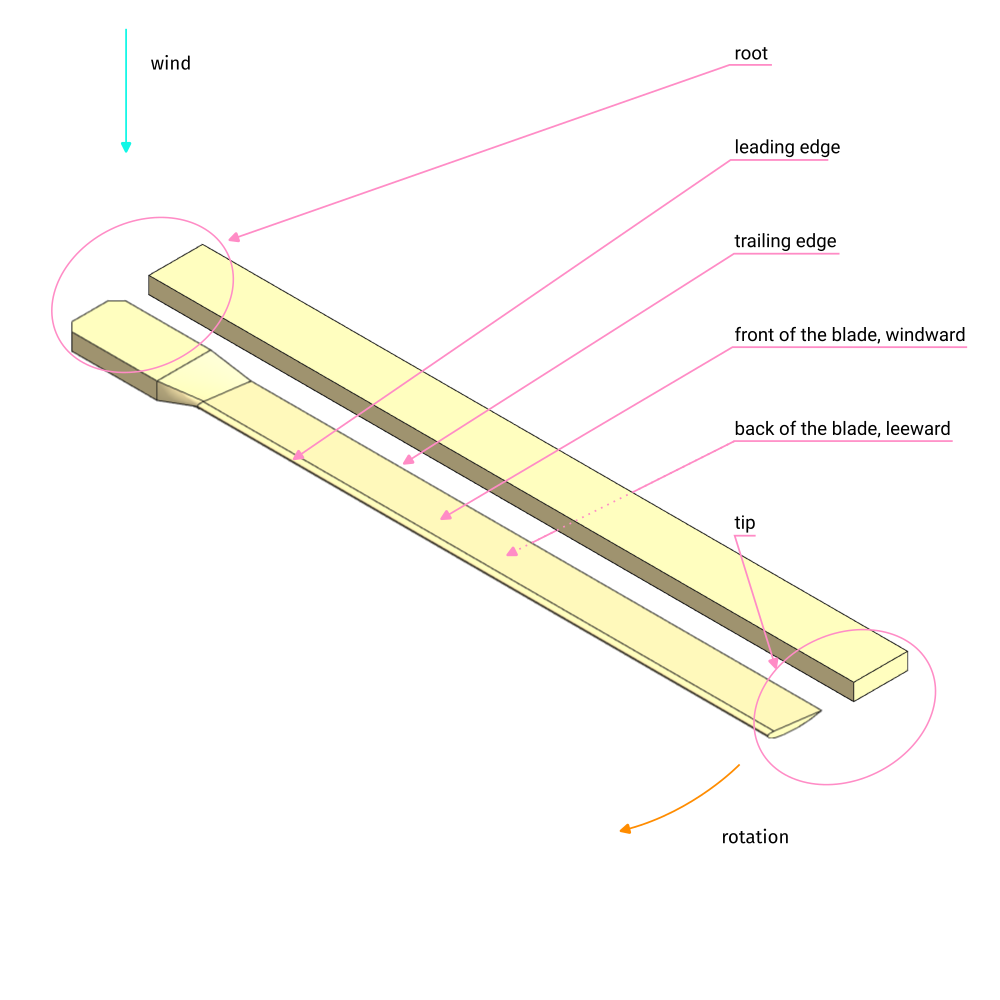

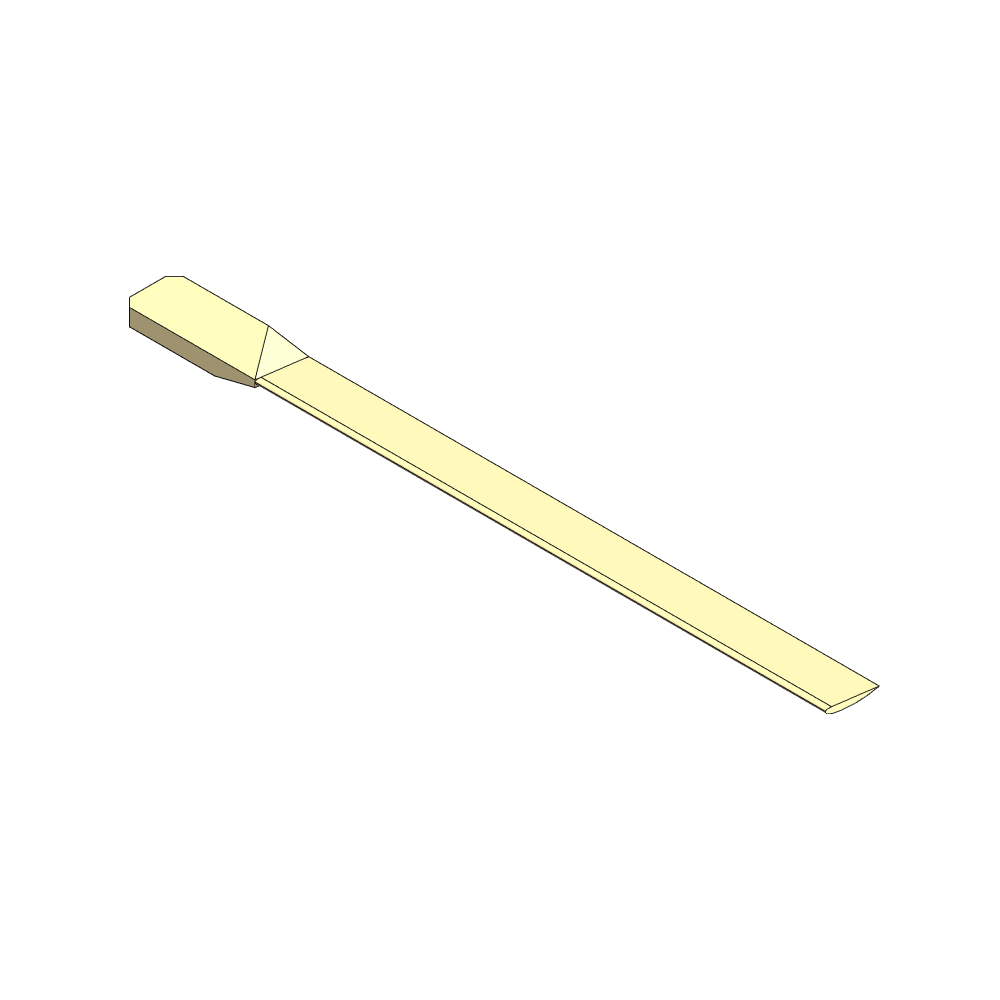

In this section we focus on carving the Rotor Blade by hand from a piece of wood. Use the CAD file to gain a better understanding of the diamensions as long as we didn't put numbers on the renderings.

This method is heavily inspired by Performance analysis and improvement of a small locally produced wind turbine for developing countries, section "Blade manufacturing manual for the new rotor design", p.111, by Nienke Hosman.

Following variables are used:

| Variables | mm |

|---|---|

| blade length R | 900 |

| wood length L | 1000 |

| blade width W | 80 |

| minimum wood thickness H | 25 |

| chord C | 80 |

| M | 200 |

| B | 67 |

| A | 33 |

| D | 10 |

| airfoil thickness T | 10 |

| a1 | 10 |

| a2 | 3 |

| a3 | 24 |

| blade angle θ | 7° |

Materials

See pos. 1 in the BOM, not all materials listed there may be required at this point.

Build

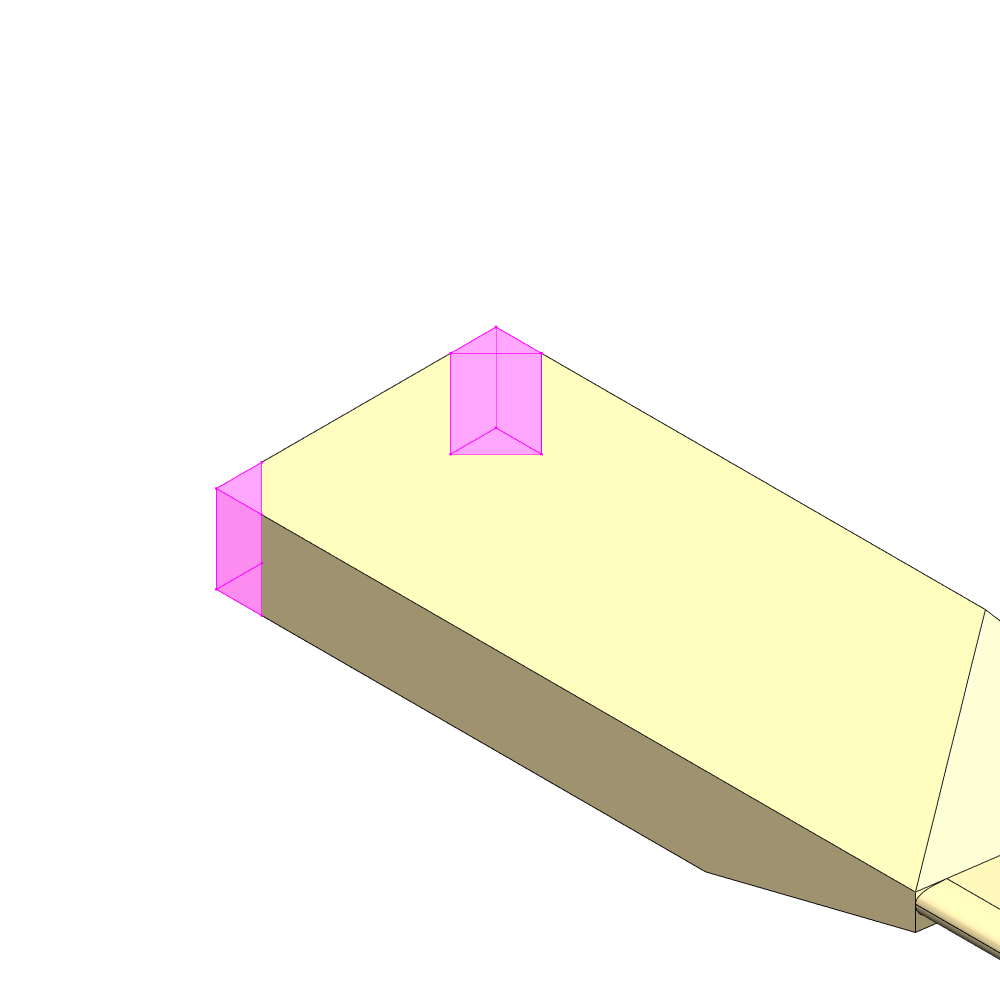

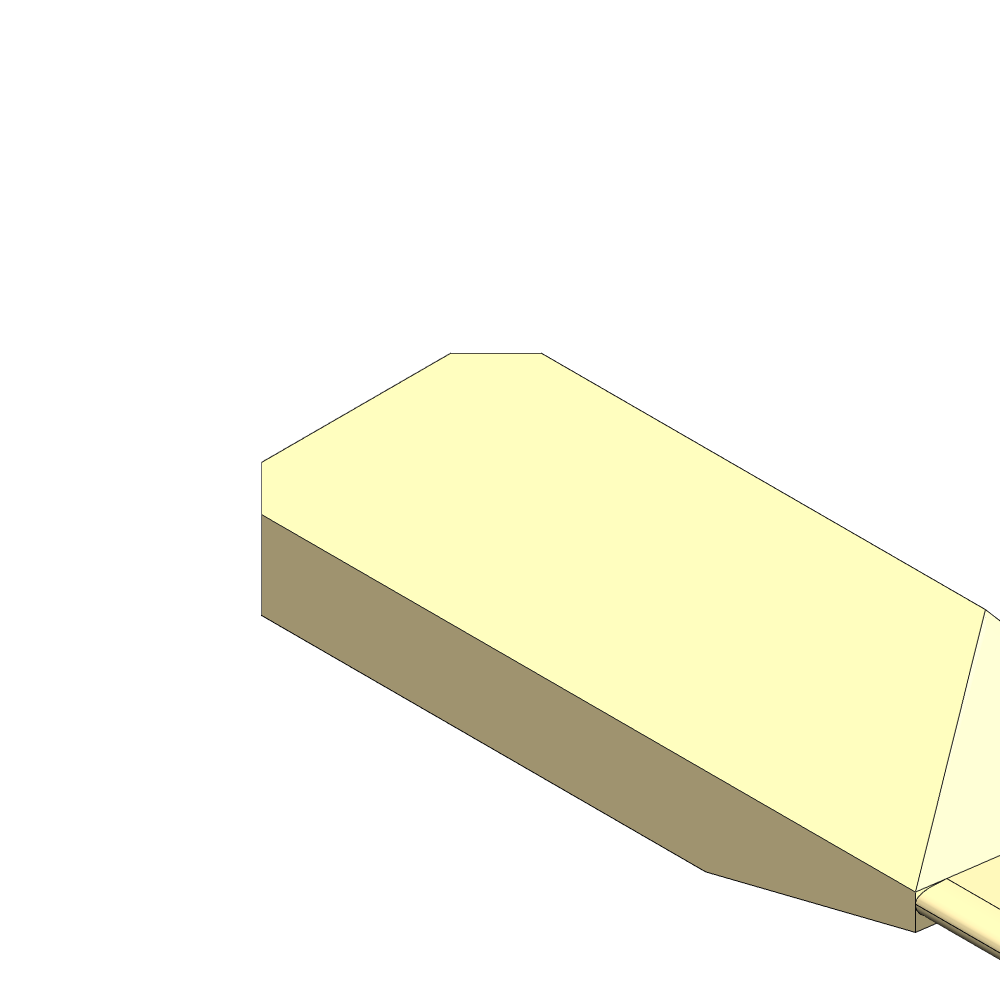

1. Define up- and downwind side of the blade

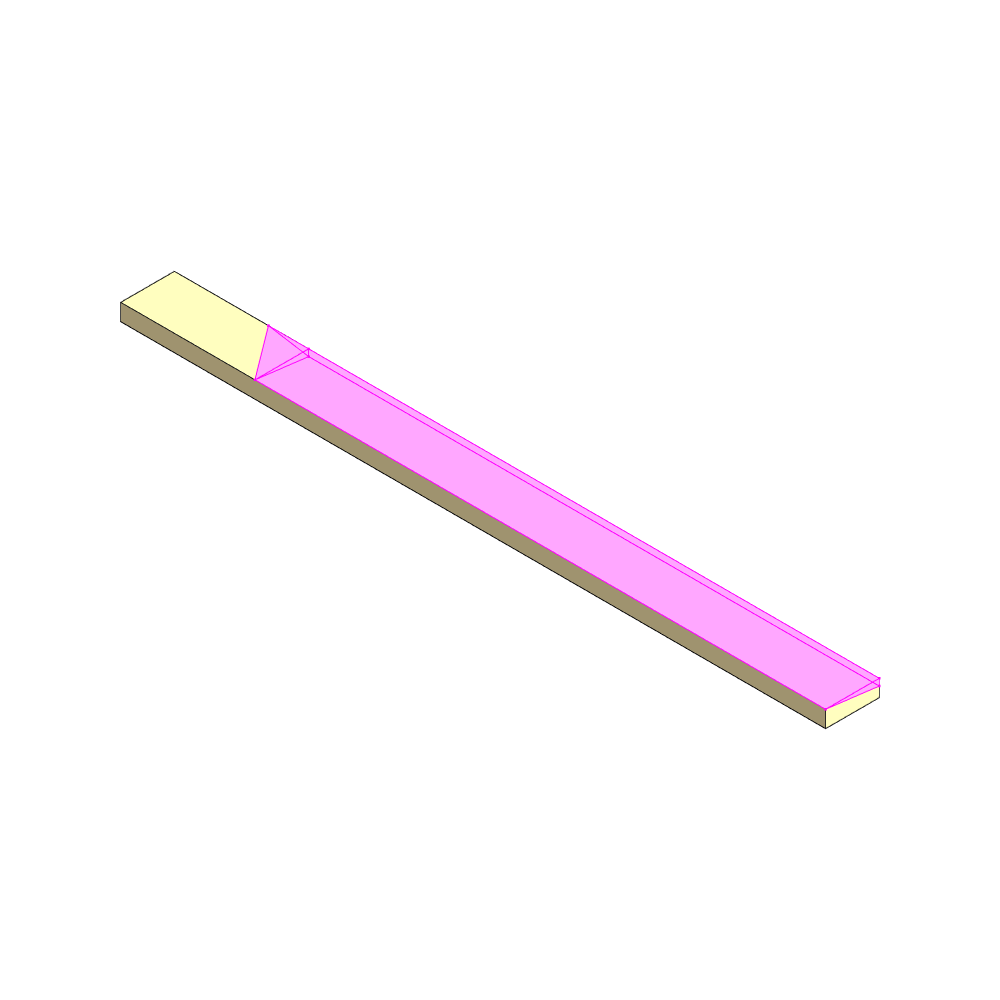

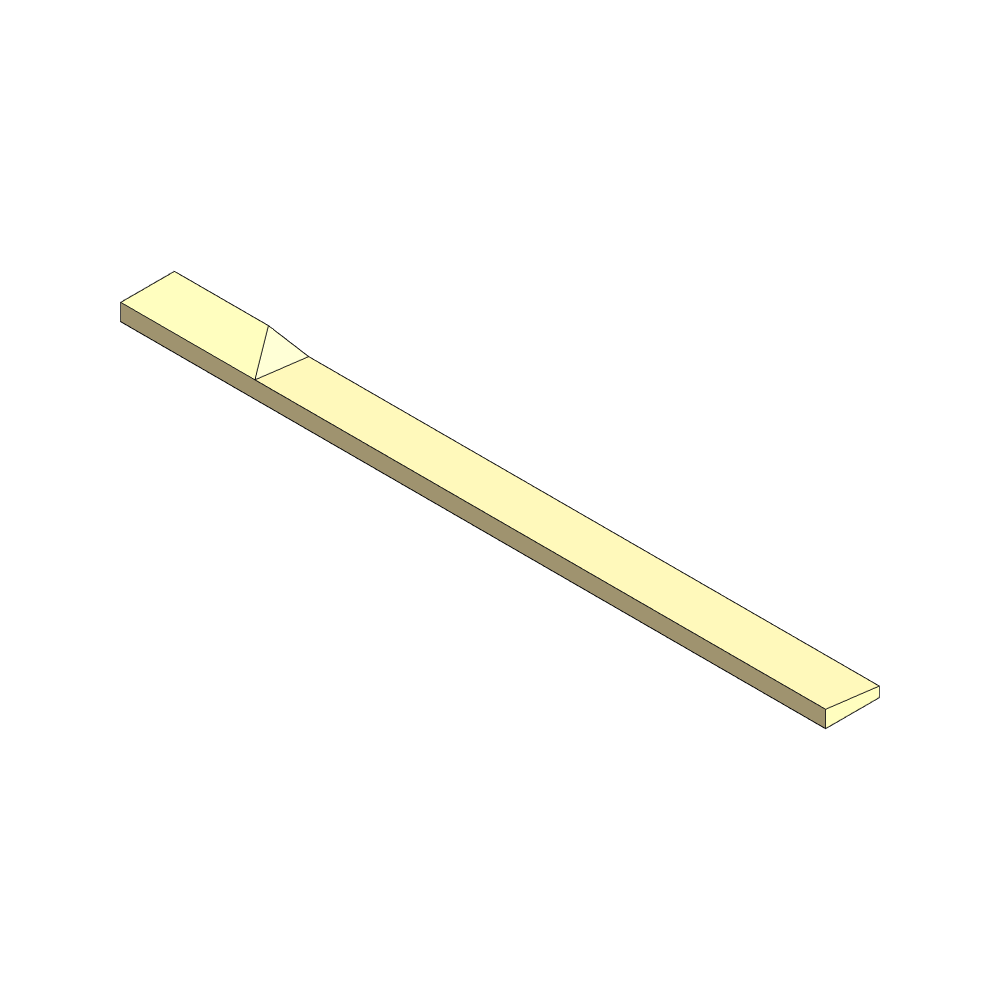

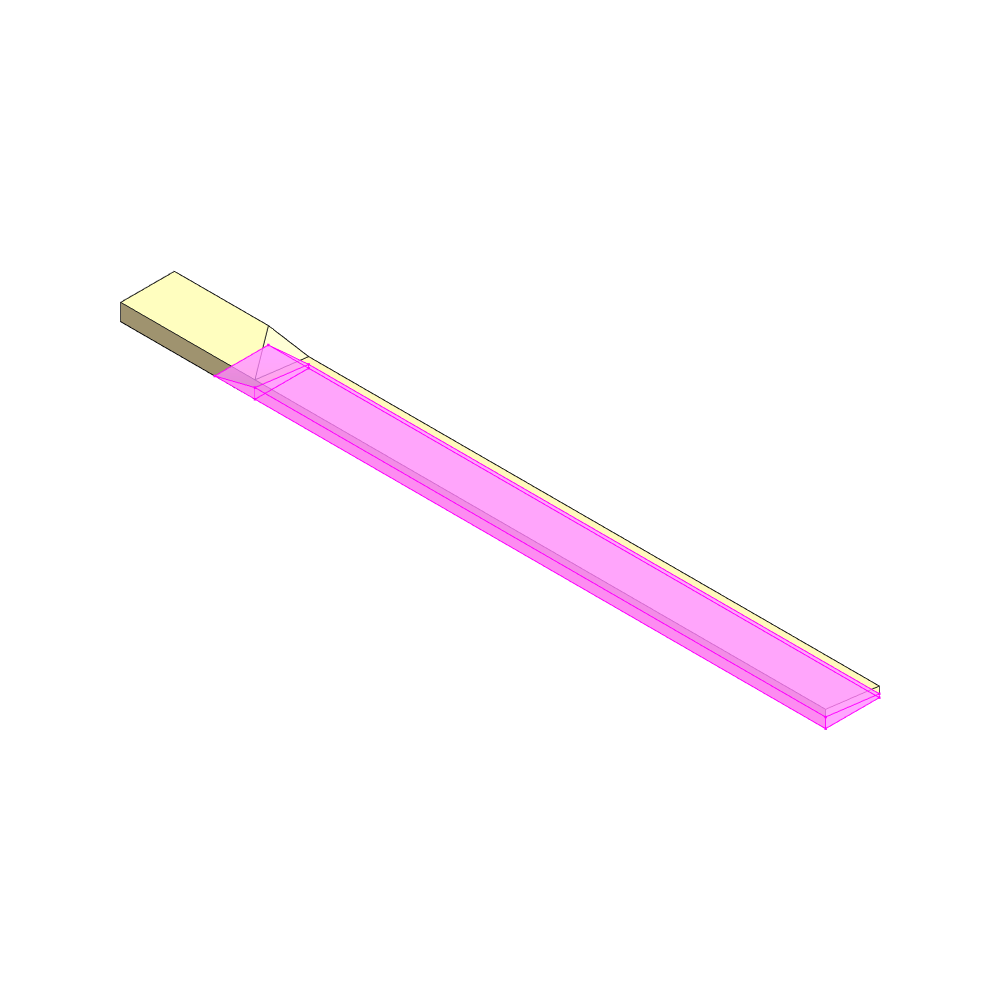

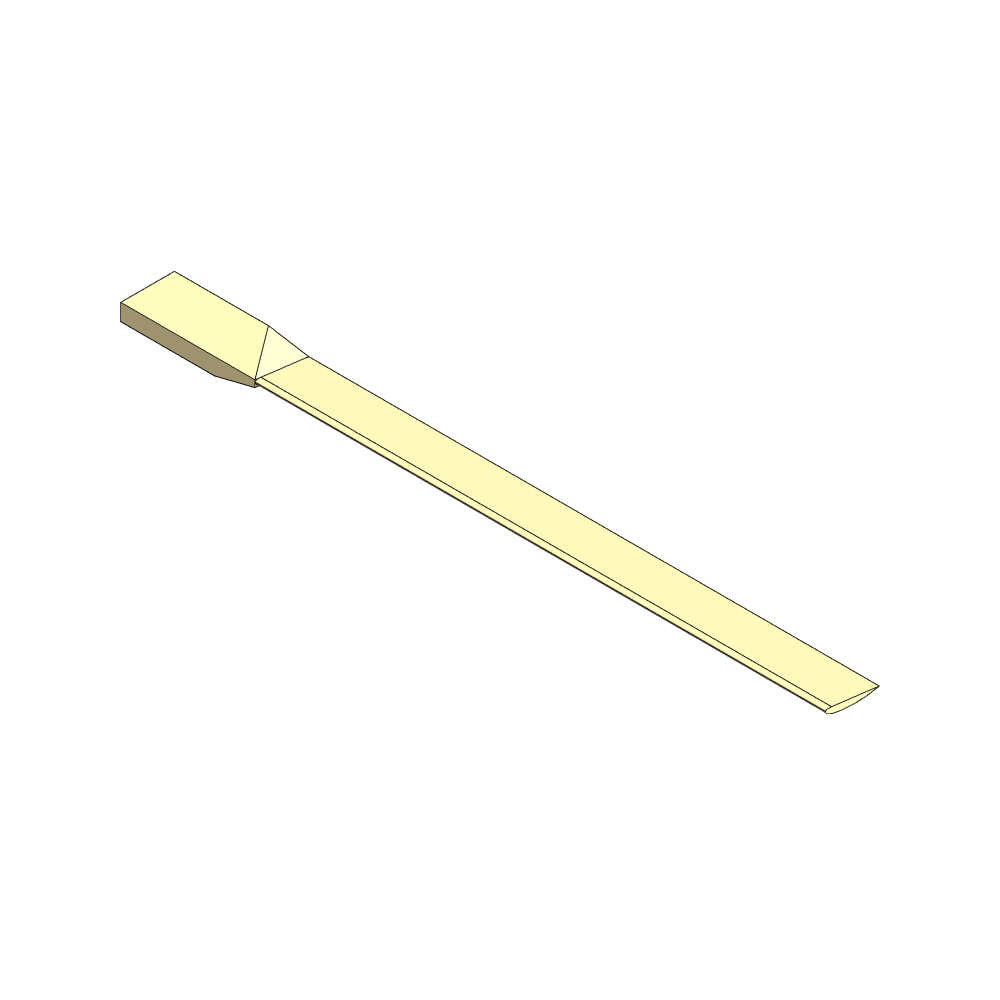

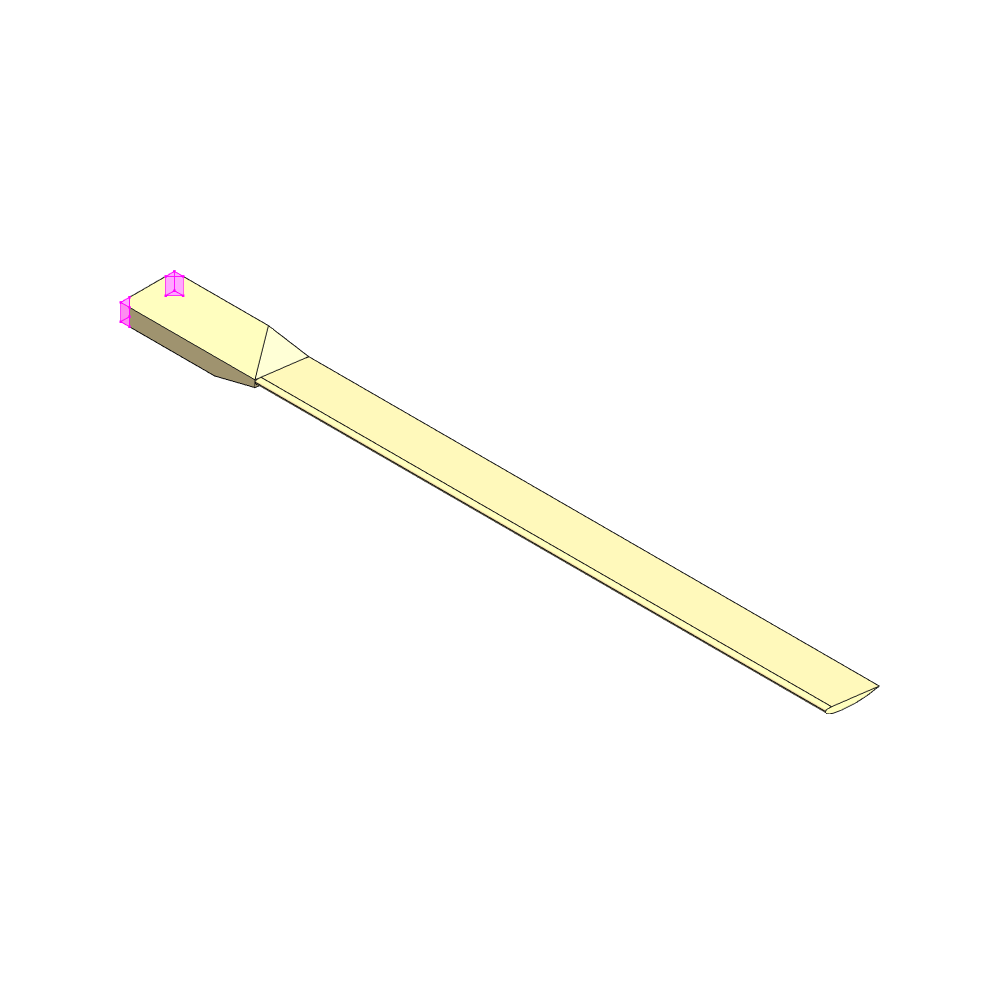

View: Perspective

View: Perspective

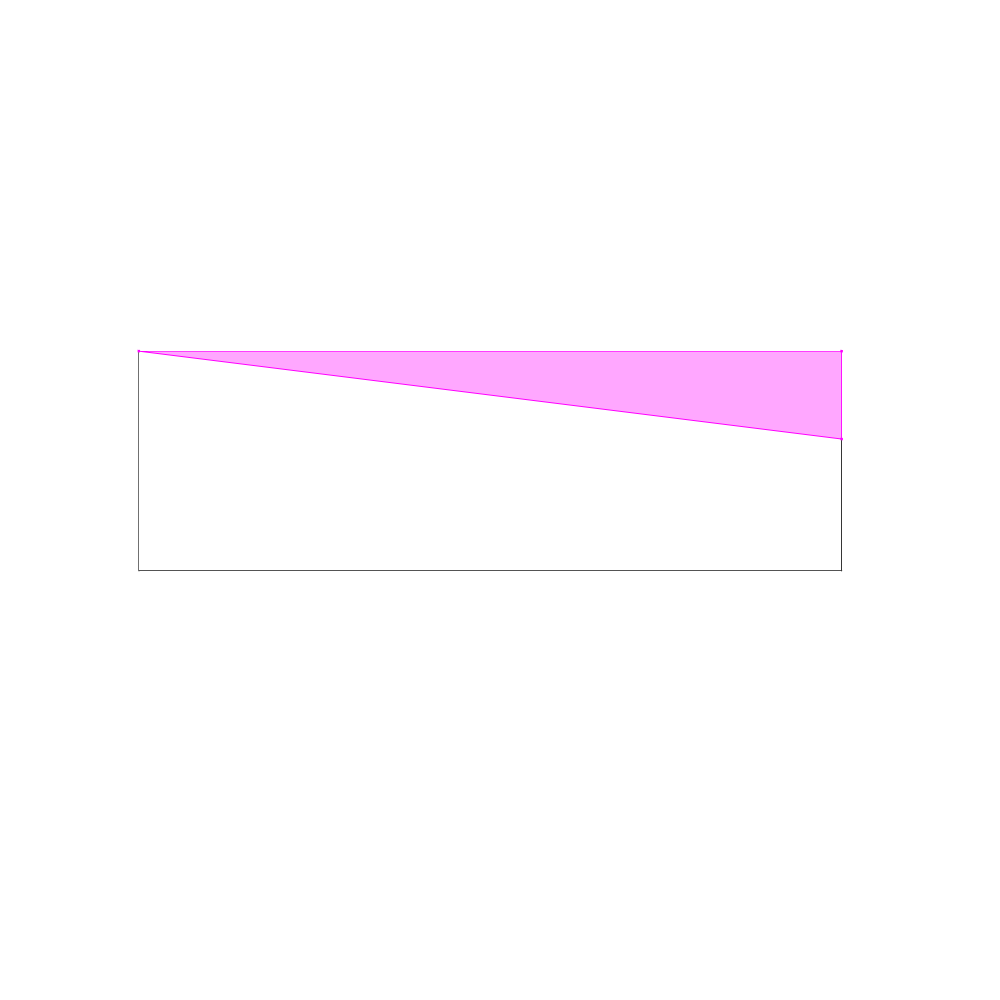

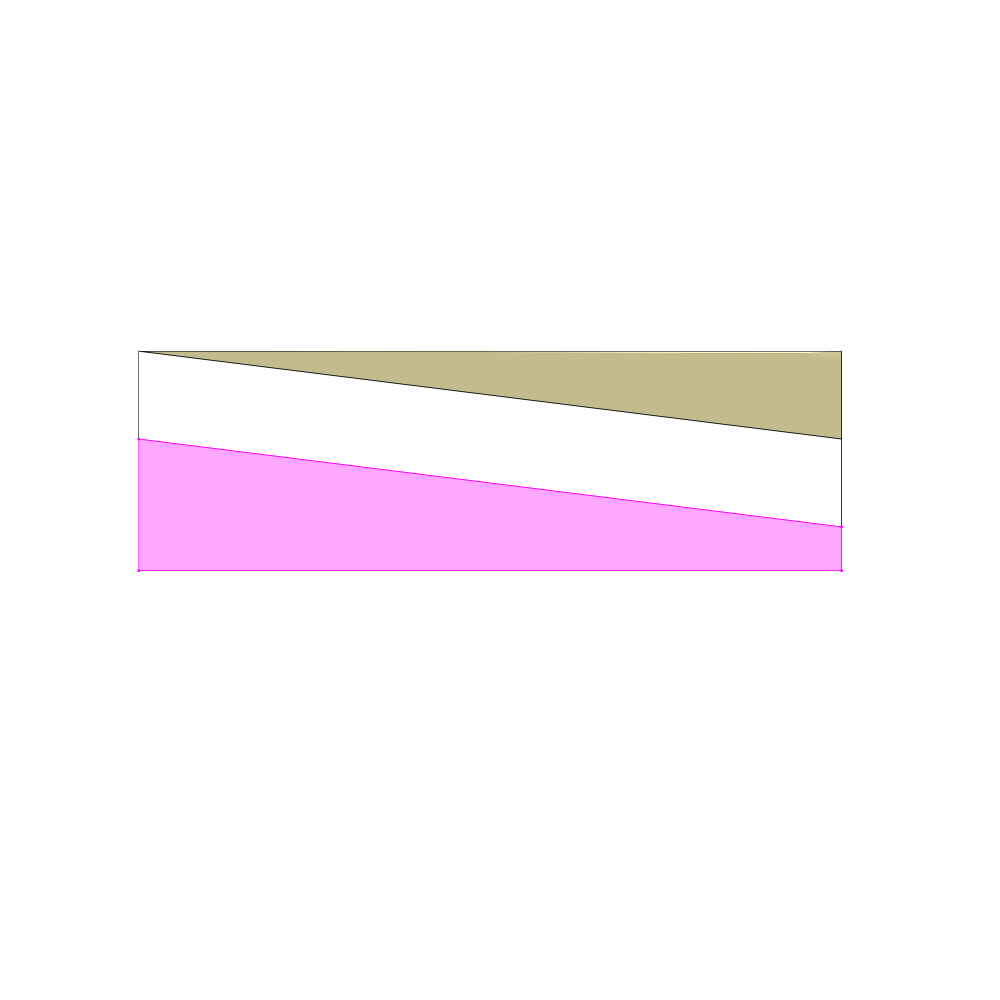

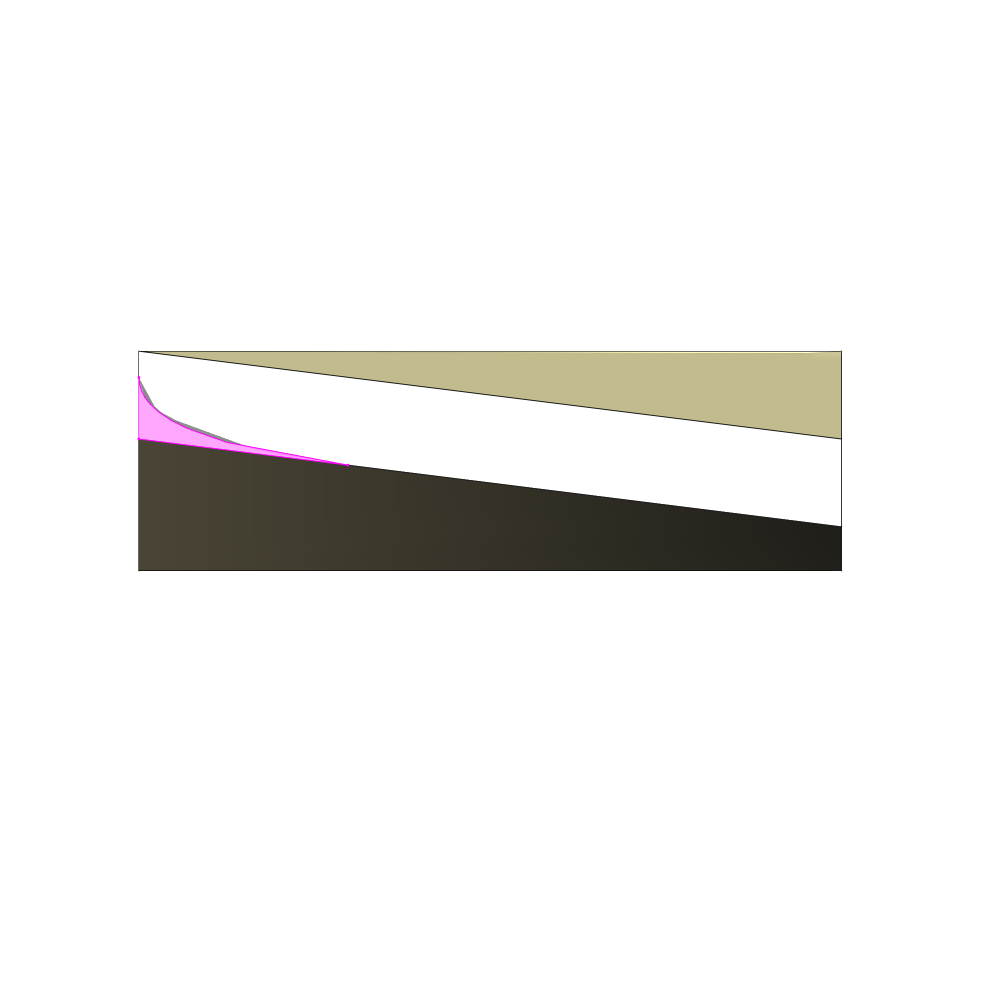

View: Looking from blade tip to root

View: Looking from blade tip to root

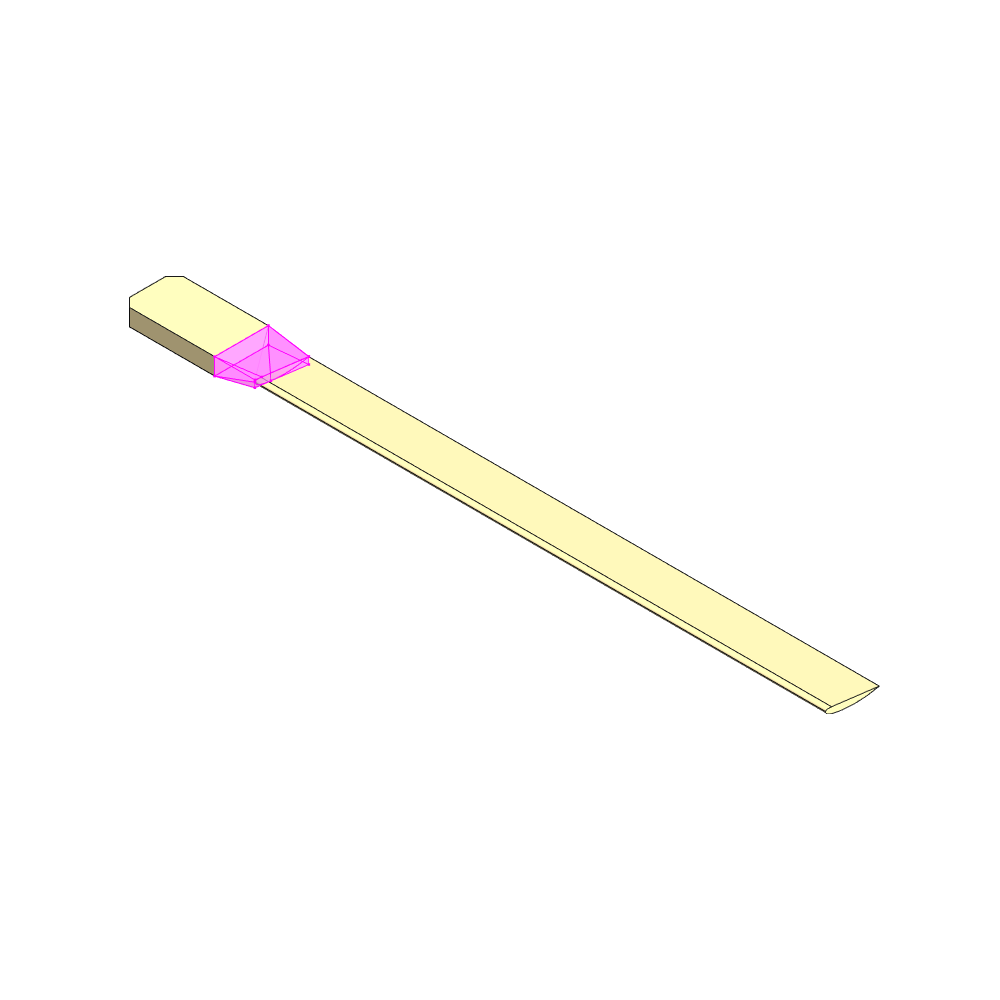

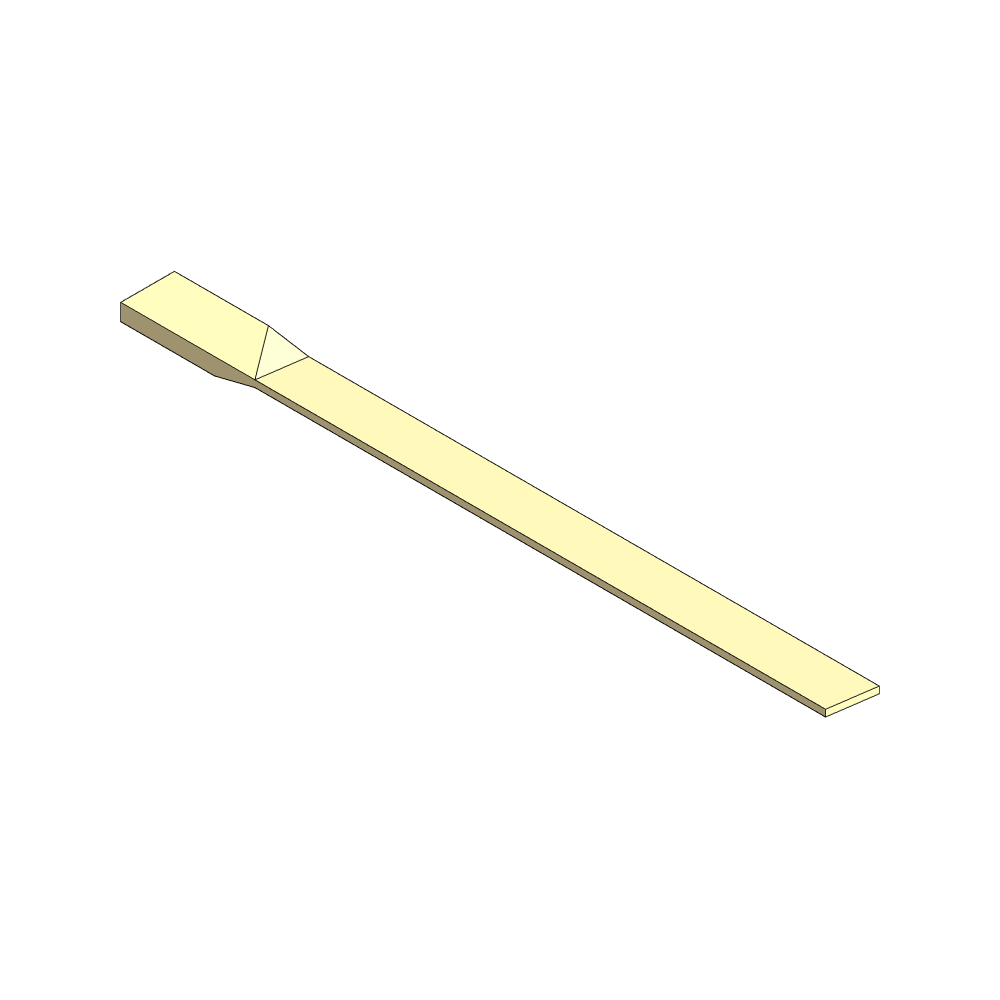

2. Carving the windward face

View: Perspective

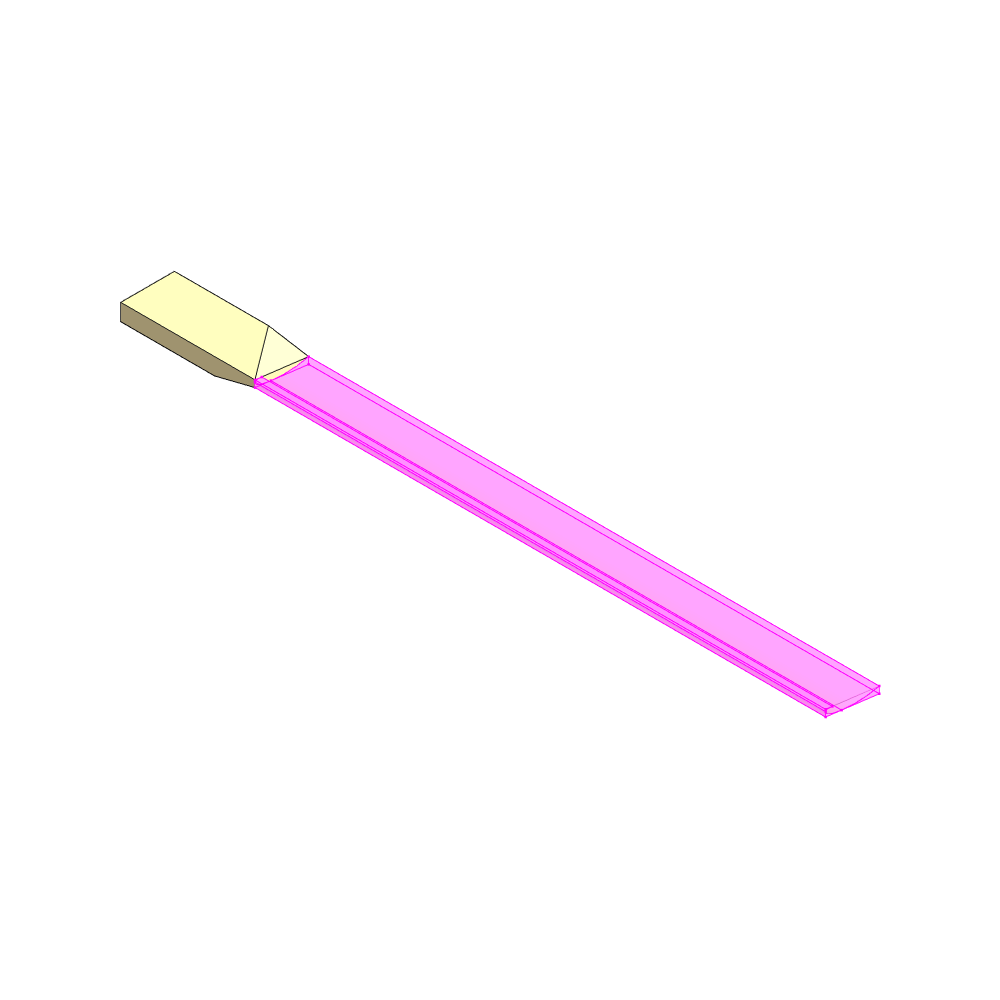

View: Perspective

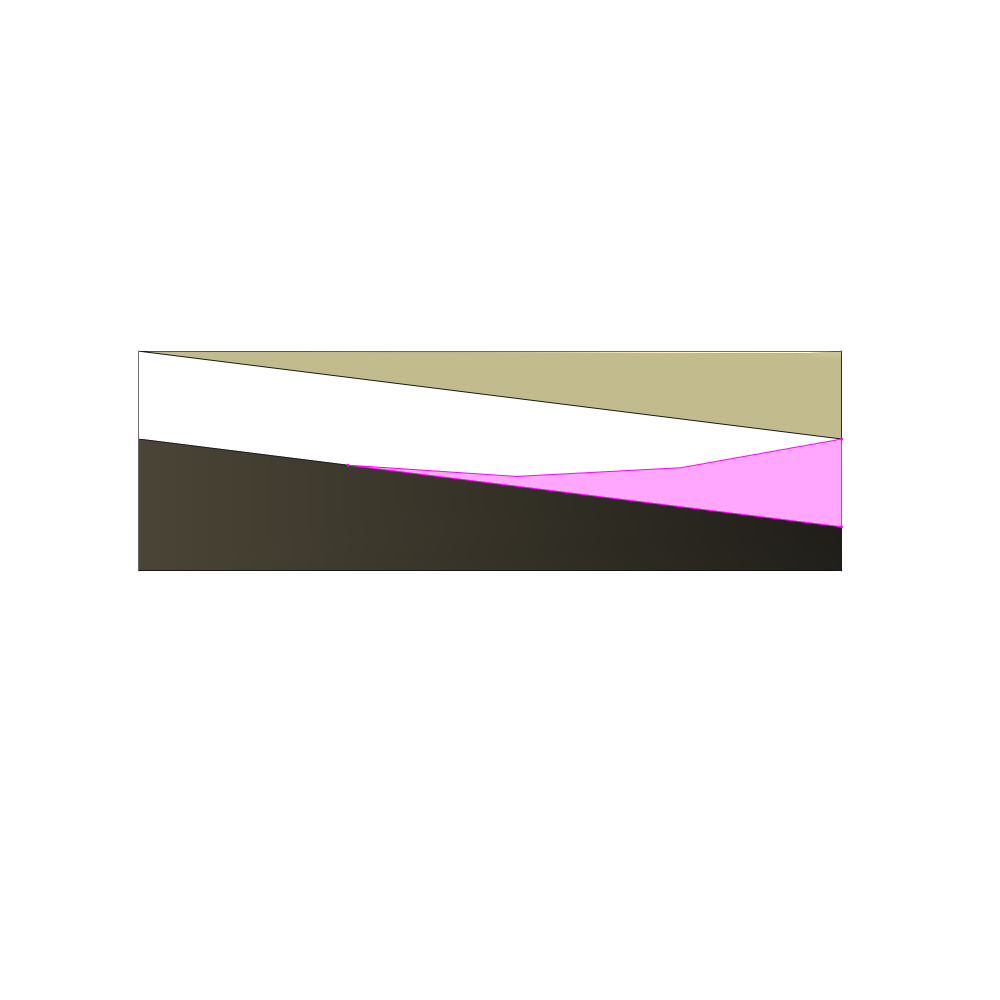

View: Looking from blade tip to root

View: Looking from blade tip to root

View: Perspective

View: Perspective

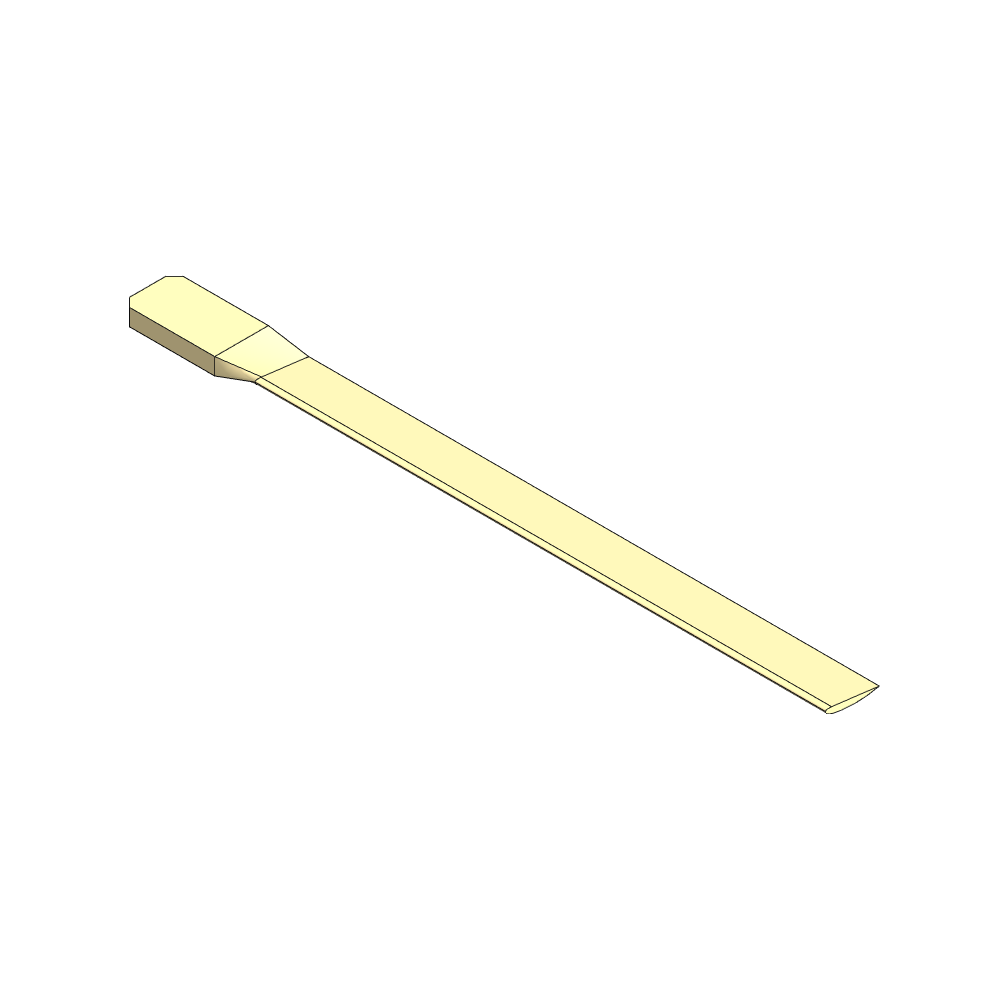

3. Carving the downwind side and blade thickness

View: Perspective

View: Perspective

View: Looking from blade tip to root

View: Looking from blade tip to root

View: Perspective upwind side

View: Perspective upwind side

View: Perspective downwind side

View: Perspective downwind side

4. Carving the airfoil shape

View: Perspective upwind side

View: Perspective upwind side

View: Looking from blade tip to root

View: Looking from blade tip to root

View: Looking from blade tip to root

View: Looking from blade tip to root

View: Looking from blade tip to root

View: Looking from blade tip to root

View: Looking from blade tip to root

View: Looking from blade tip to root

View: Perspective upwind side

View: Perspective upwind side

5. Cut the edges of the root

View: Perspective upwind side

View: Perspective upwind side

View: Perspective blade root

View: Perspective blade root

View: Perspective blade root

View: Perspective blade root

View: Perspective upwind side

View: Perspective upwind side