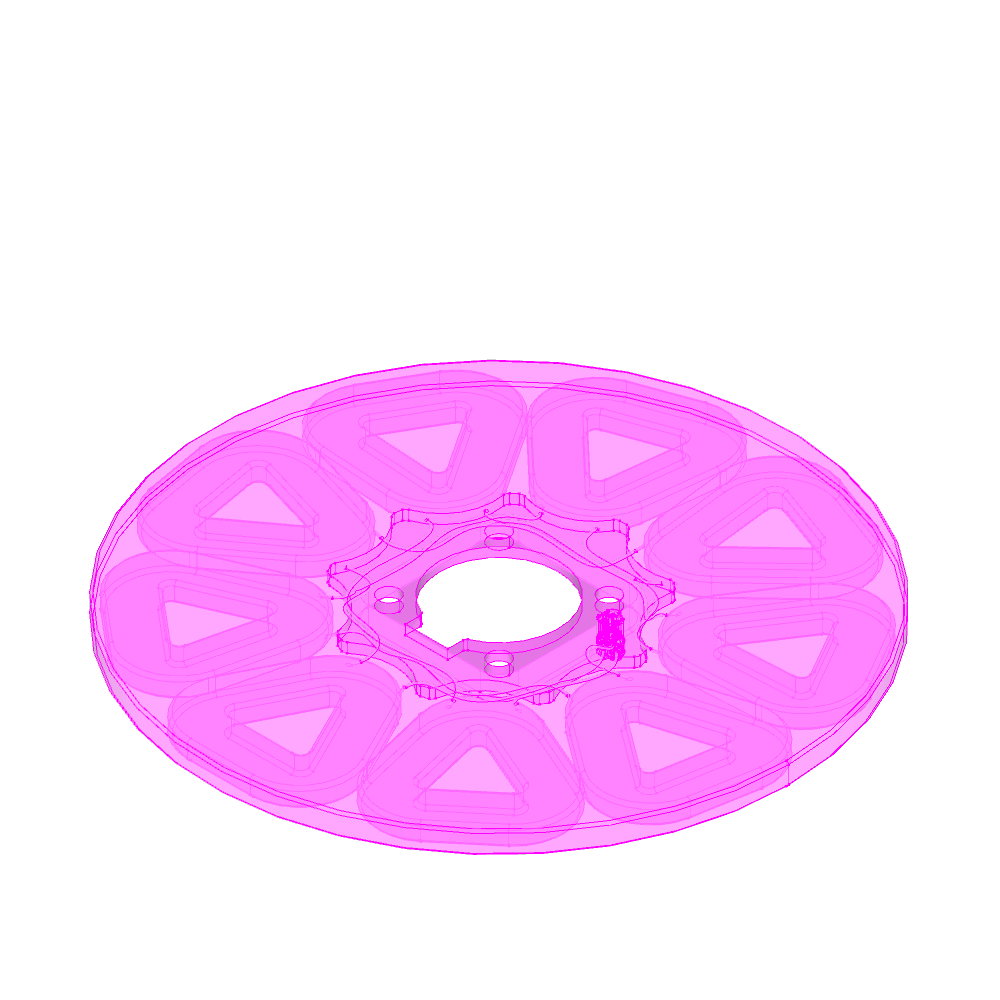

- Overview

-

Assembly

- 1.Nacelle - Alt.Stator

- 2.Shaft

-

3.Altnator Rotor

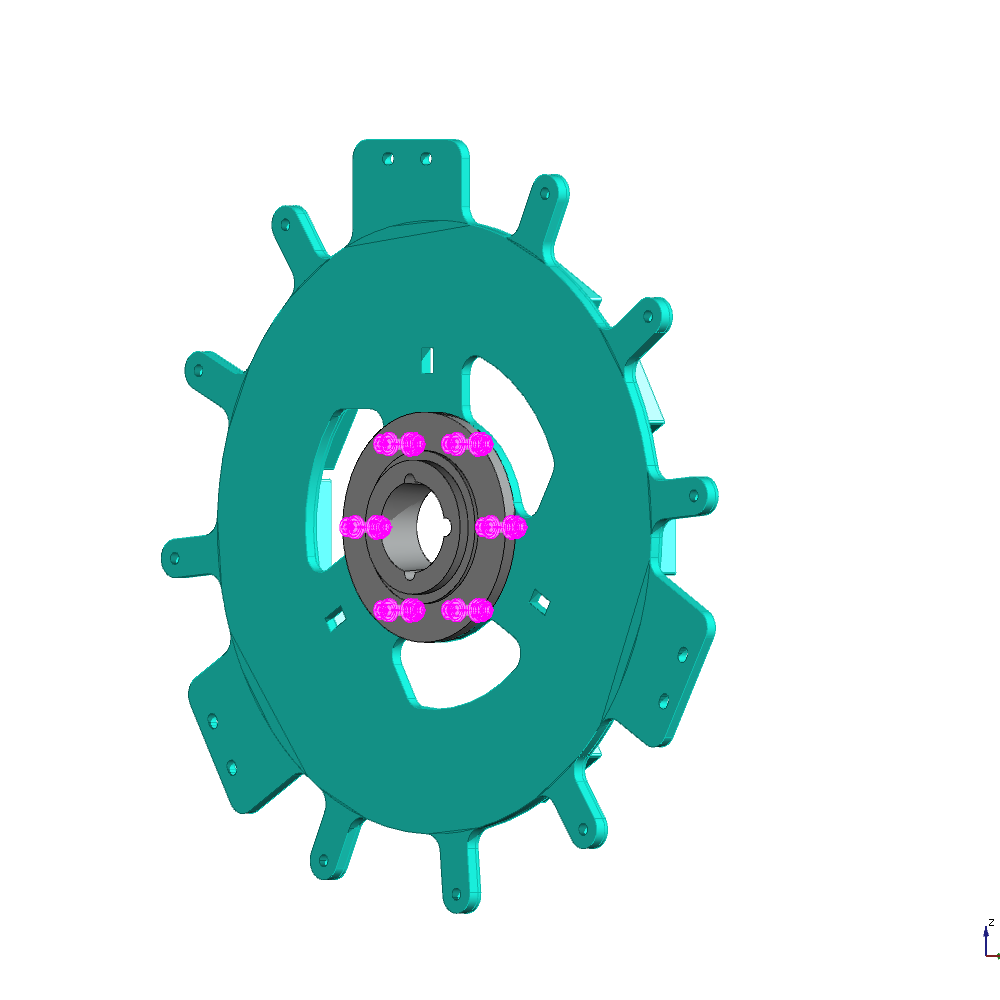

- Place the Taper Bush Hub

- Mount on the Taper Bush Hub

- Place the Taper Bush

- Loosly tighten the Taper Bush Set Screw

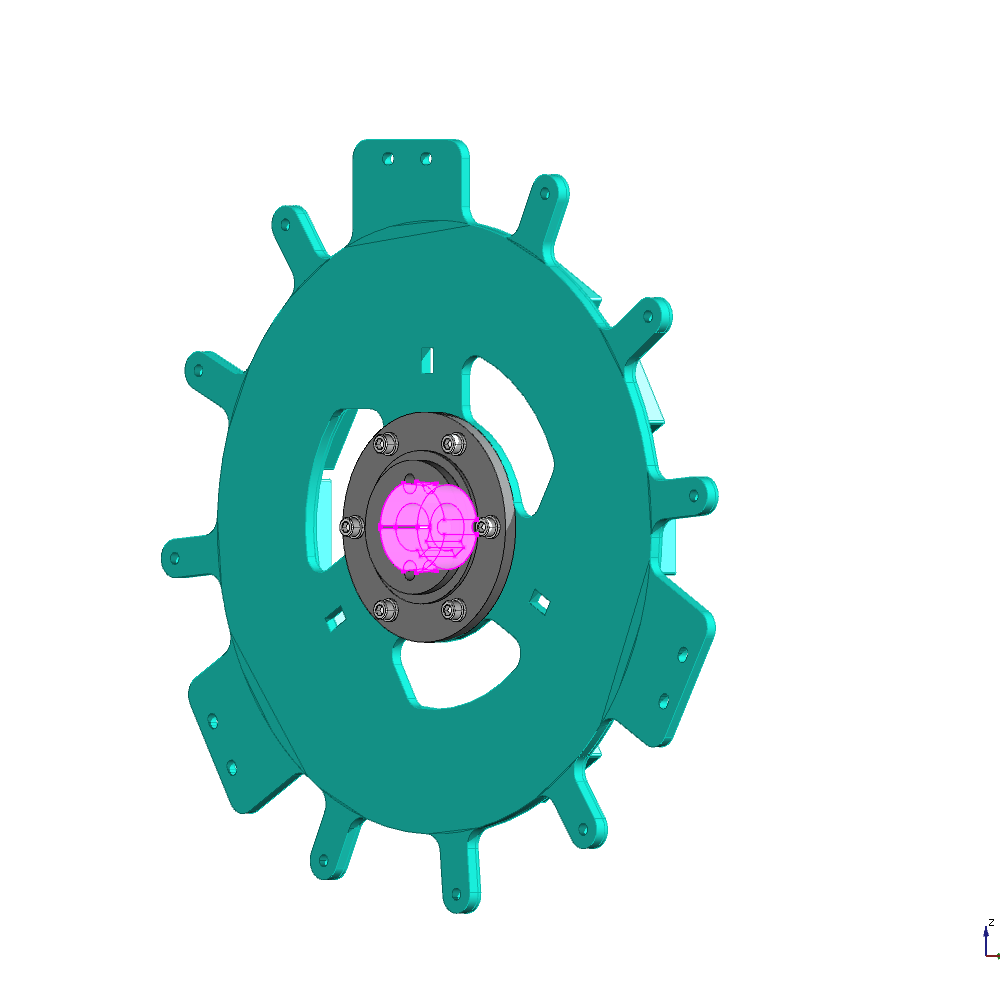

- Place the Upwind Magnet Disk onto the Shaft

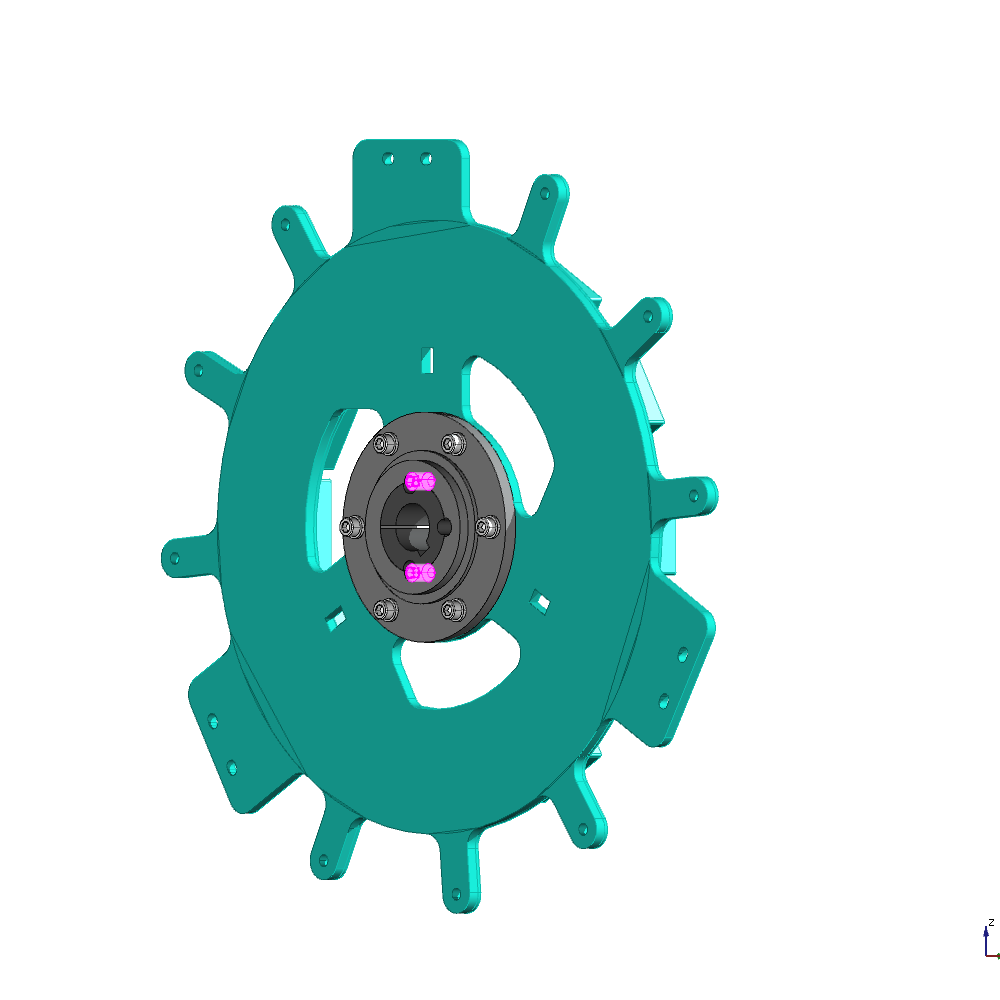

- Tighten the Taper Bush Setscrews

- Add the Disk Fasteners

- Add the Spacer Sleeves

- Add Downwind Magnet Disk

- Tighten the Alternator Stator

- Measure the airgap

- Alternator is ready to be used

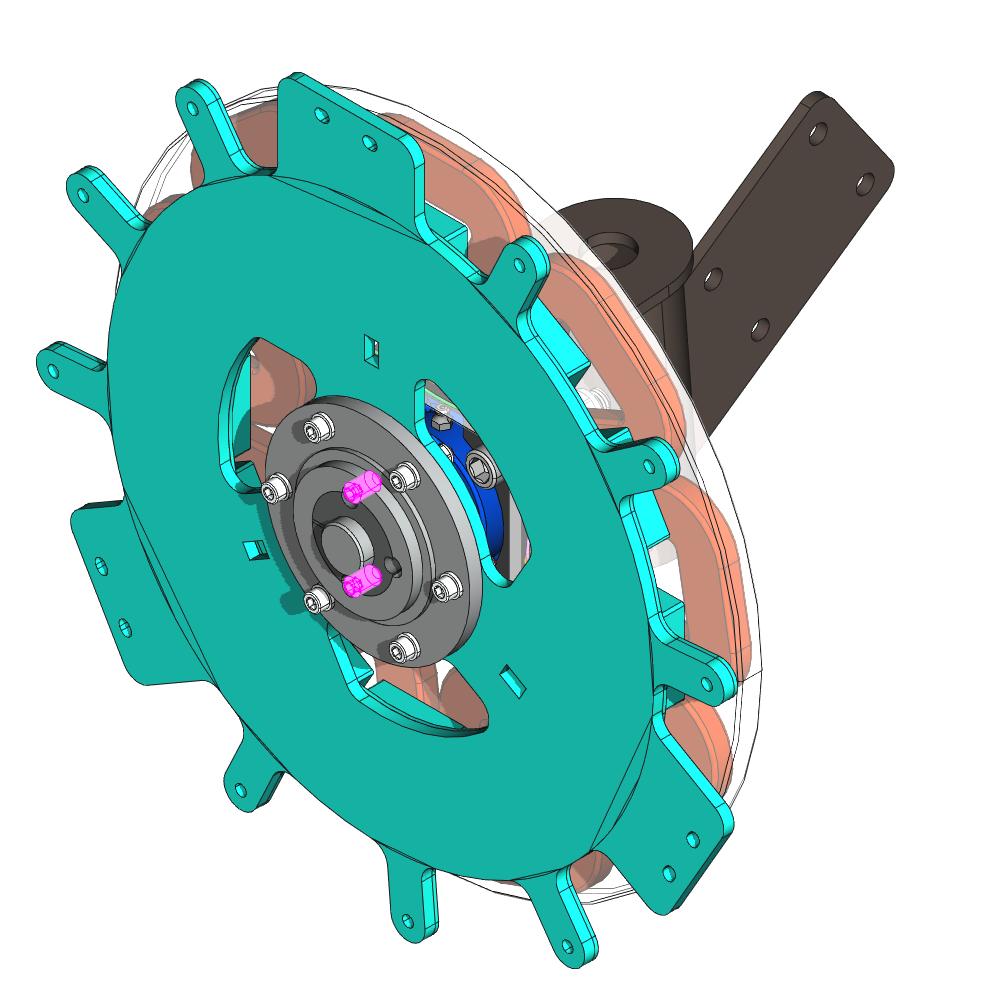

- 4.Rotor

- 5.Windvane

- Cable

Overview

In this chapter we will focus how to set all parts together, we also call it the marriage a polyamouros one you can say. Nacelle, Alternator, Rotor and the Wind Vane we be mounted together. Ét voila the windkit is ready to produce energy. We'll start with the Nacelle and the Alternator Stator.

Assembly

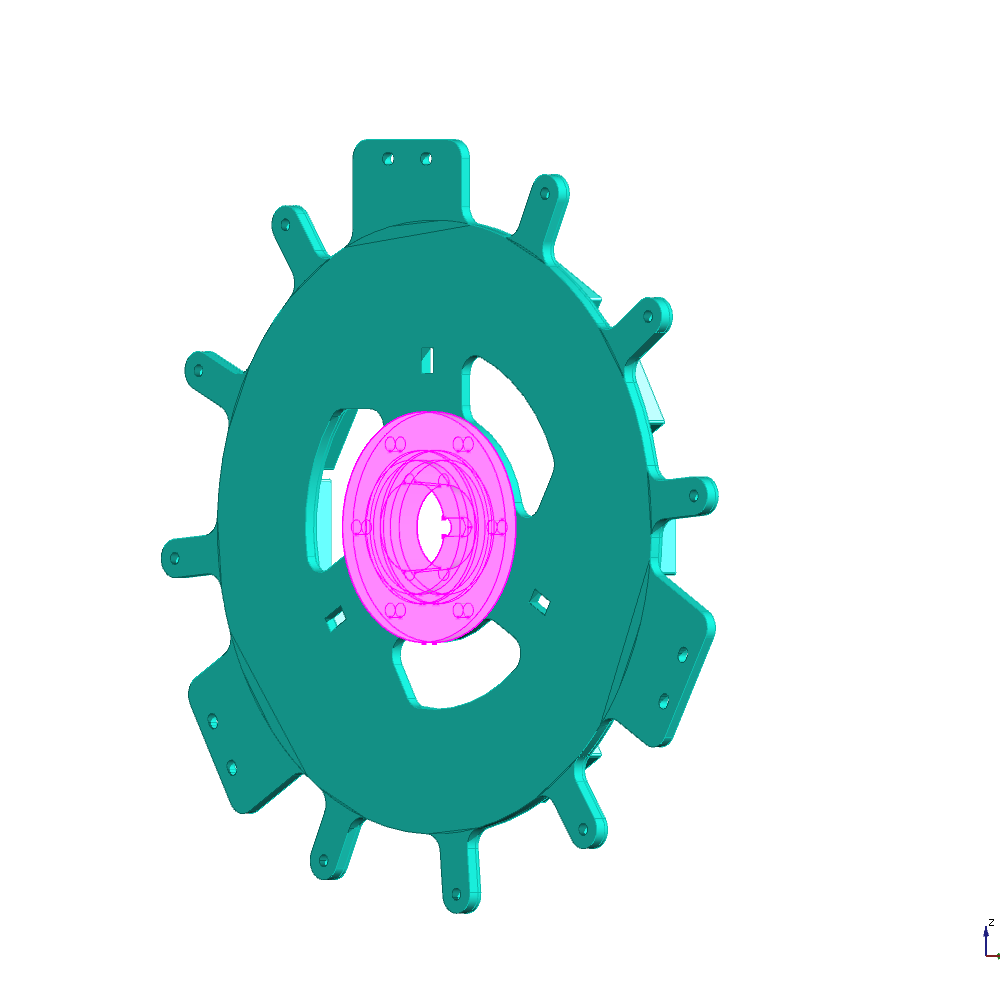

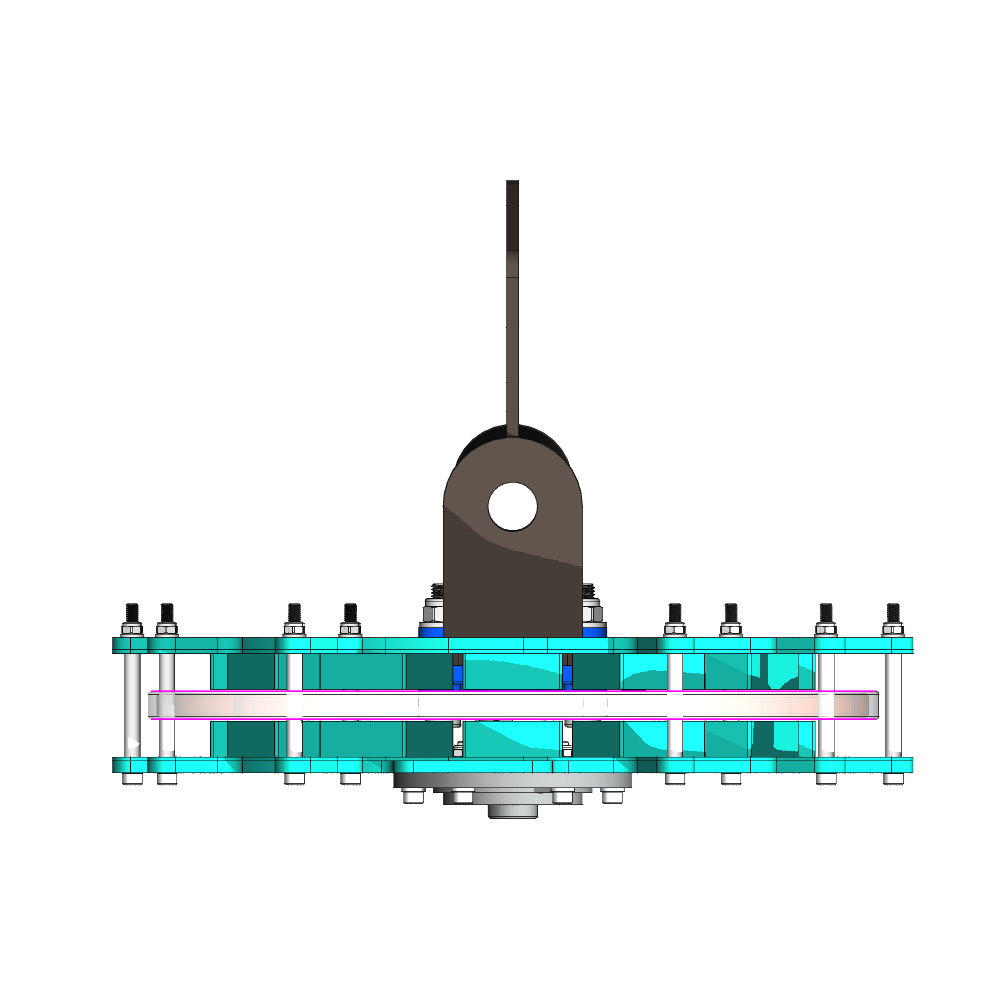

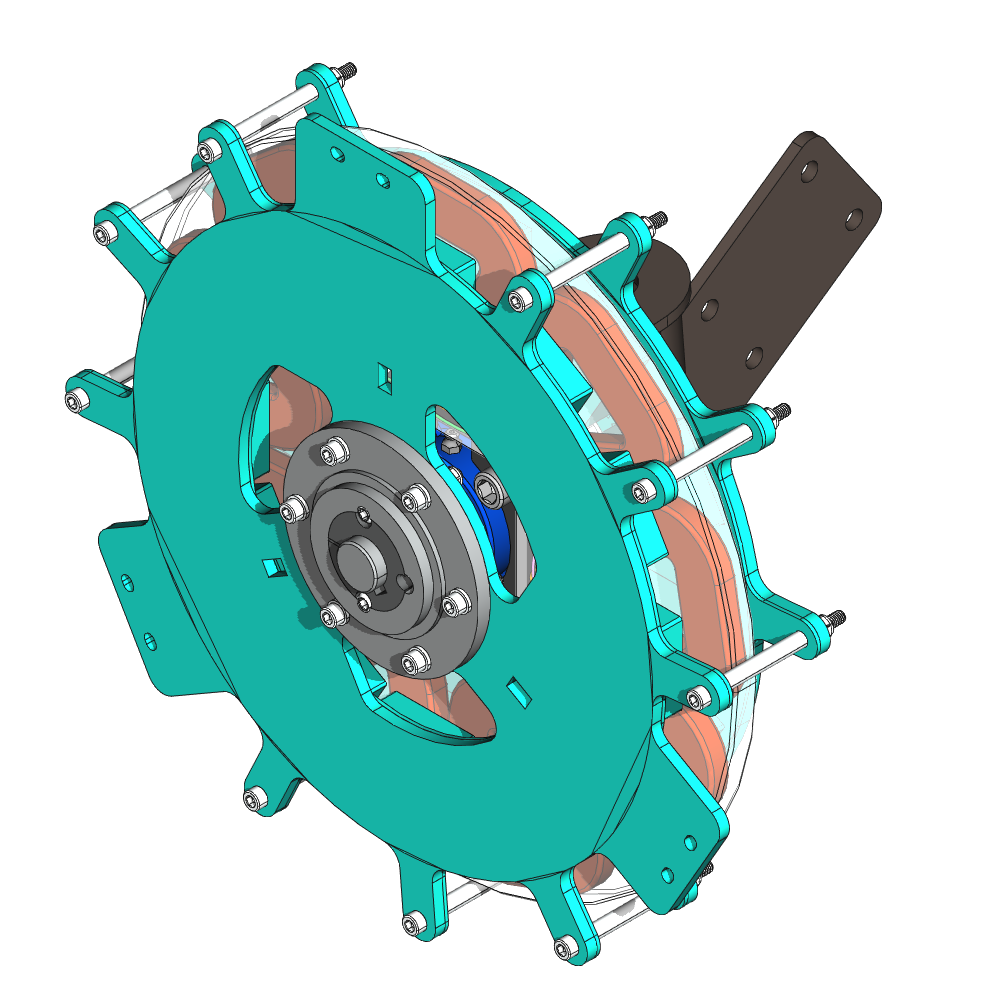

1.Nacelle - Alt.Stator

Place the Alternator Stator front facing down

Place Bolts underneath

4x M12x60-Screw without washers

Place first Housing Bearing

Mounting side up 1x UCF205

Take care of the grease nipple

Place Nacelle

Place second Housing Bearing

1xUCF205 Mounting side down

Loosly tighten the Nuts

4x M12-Washer 4x M12-Nut

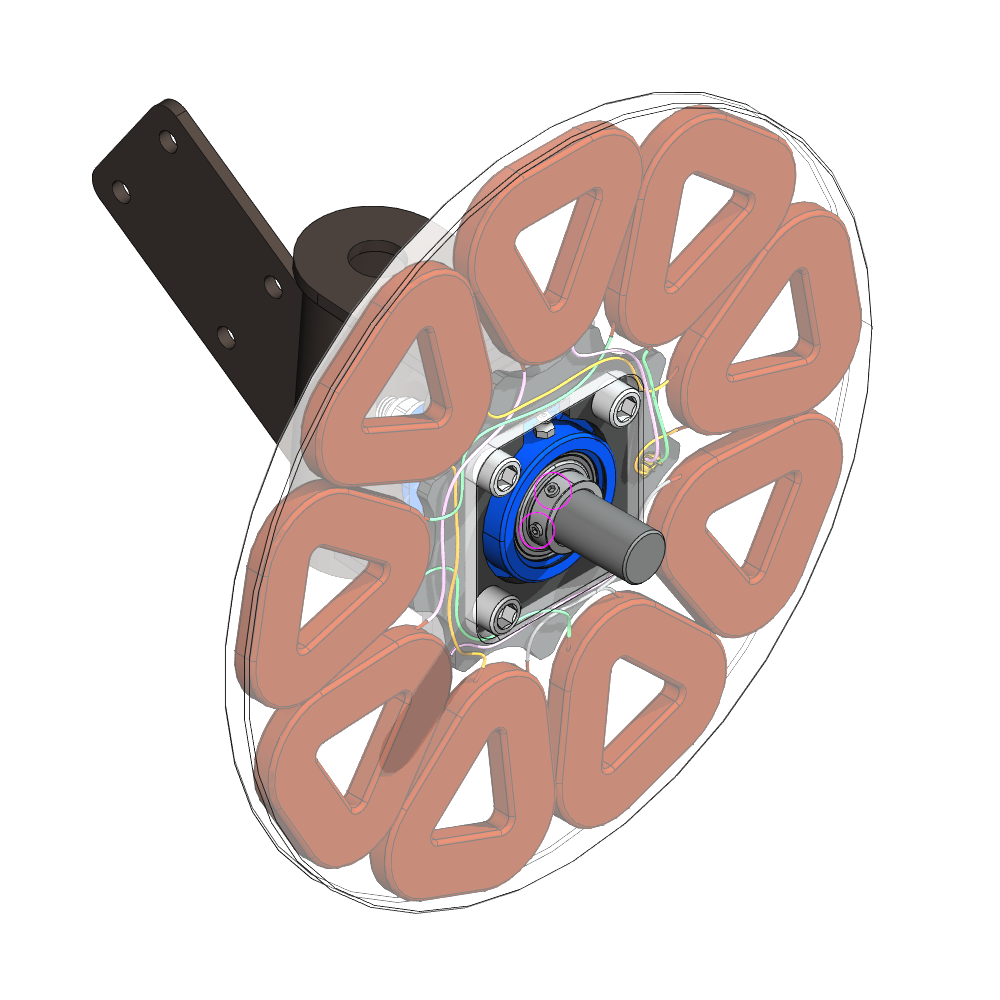

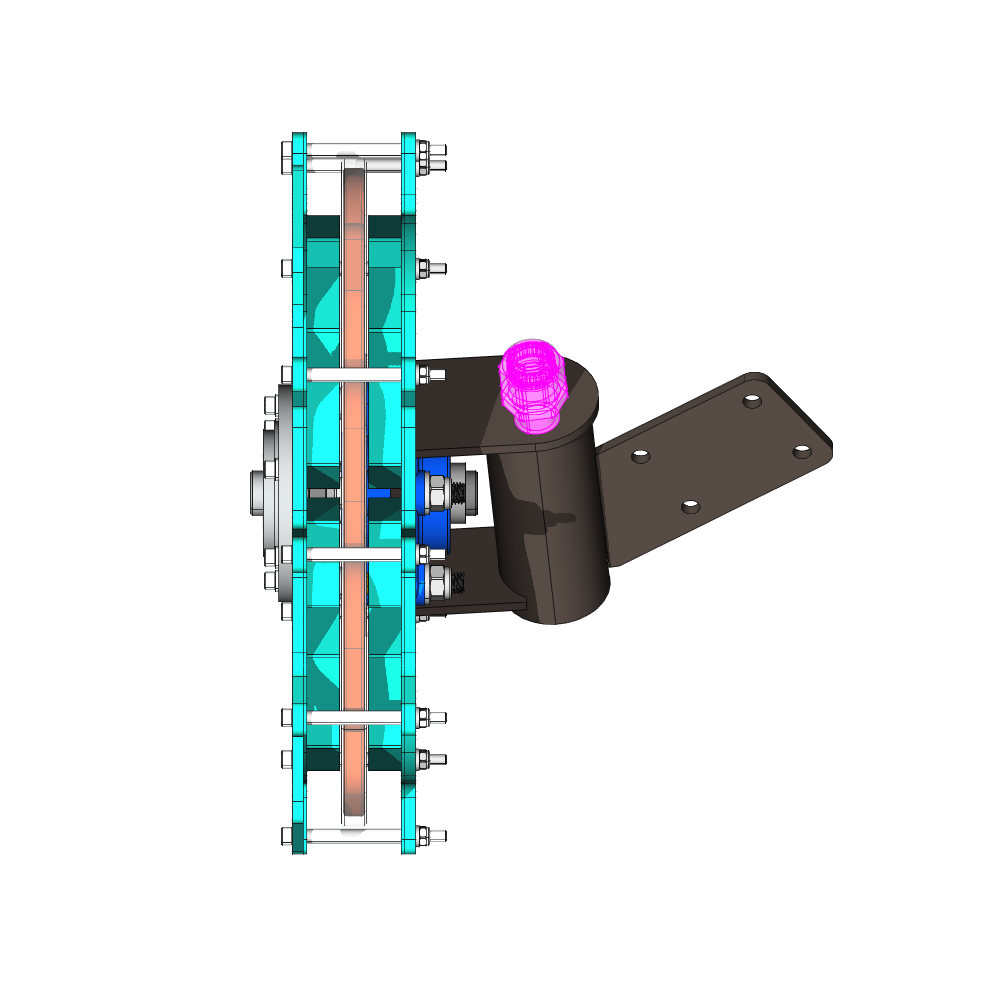

2.Shaft

Place the Nacelle on a piece of 2" pipe for the next steps.

Place the Shaft

Tigthen the nuts

Tigthen the setscews of bearing

There are 2 setscrews per bearing, tighten them one after the other.

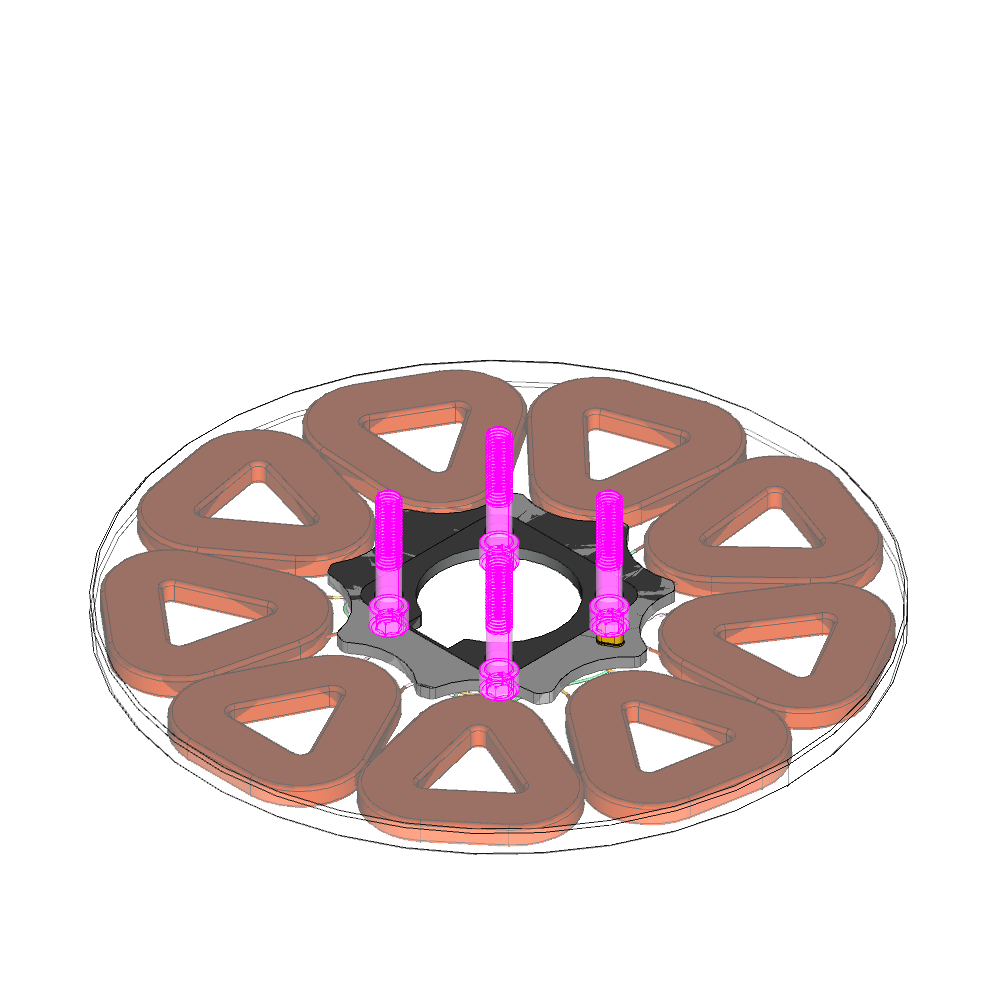

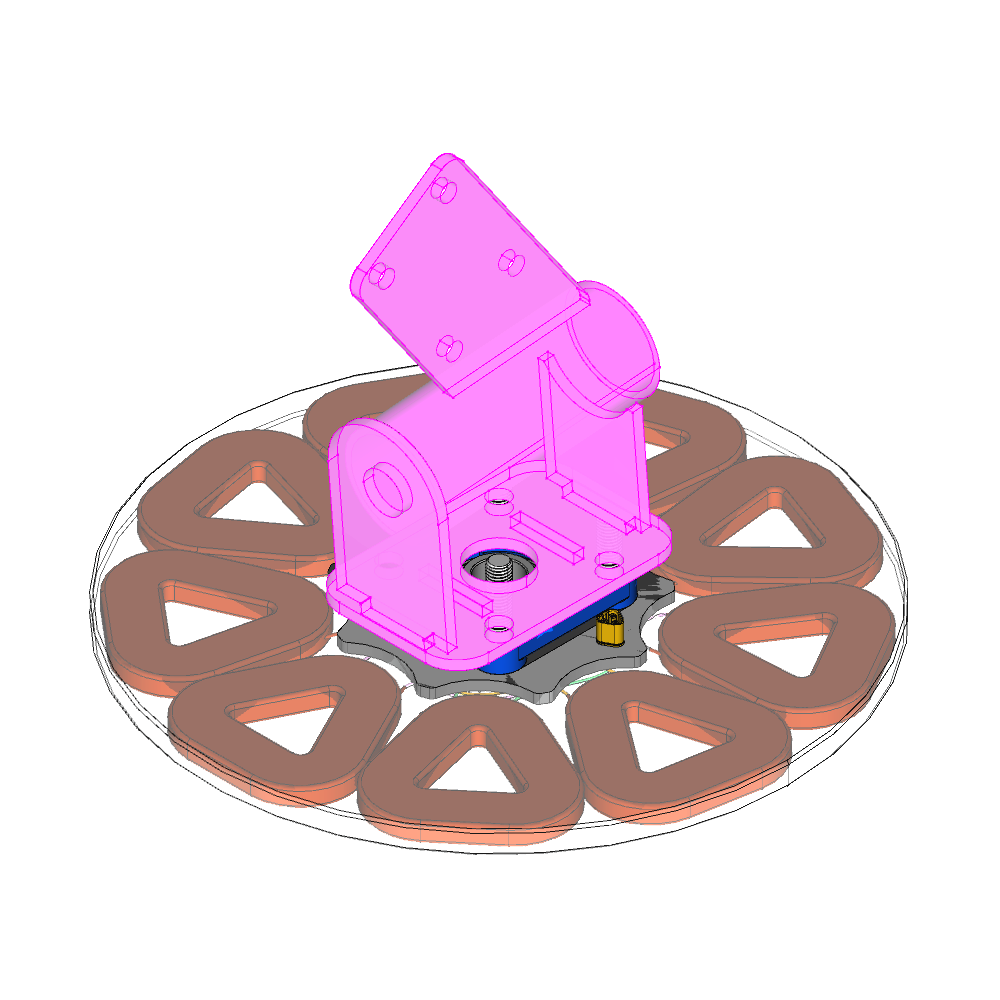

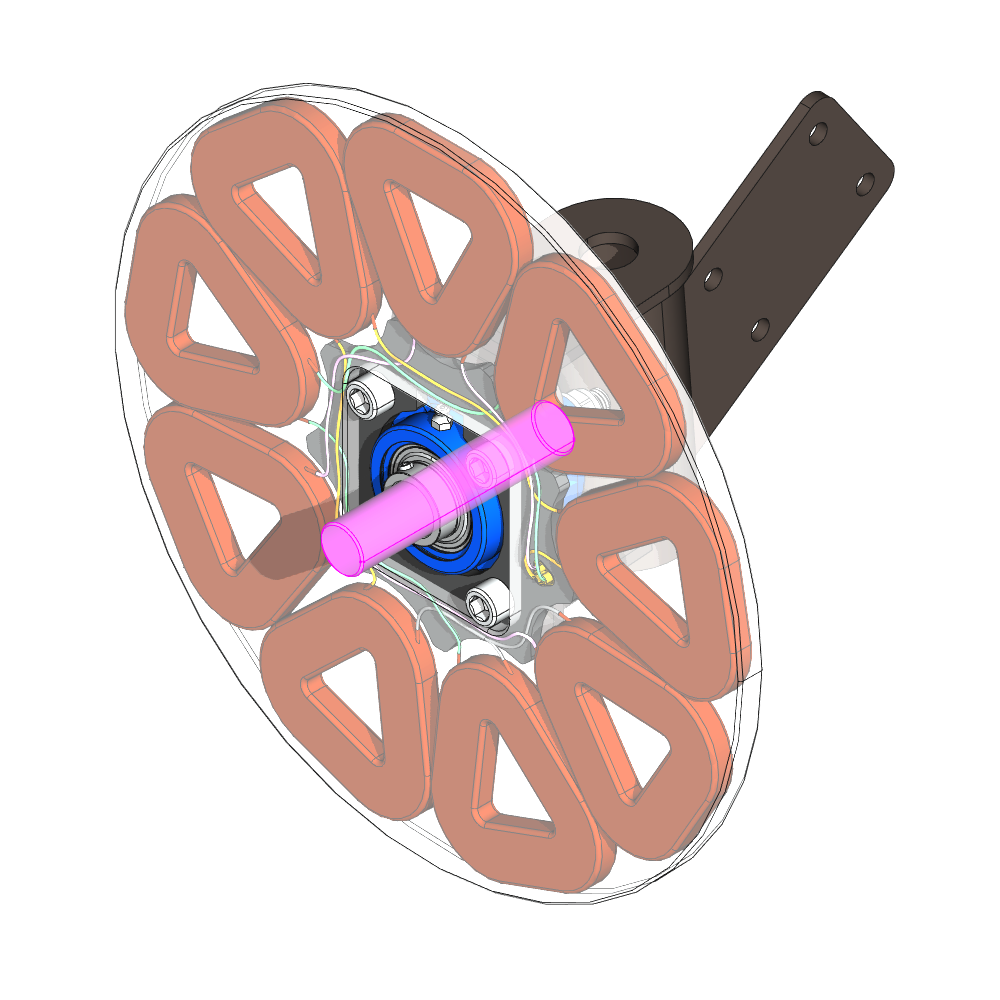

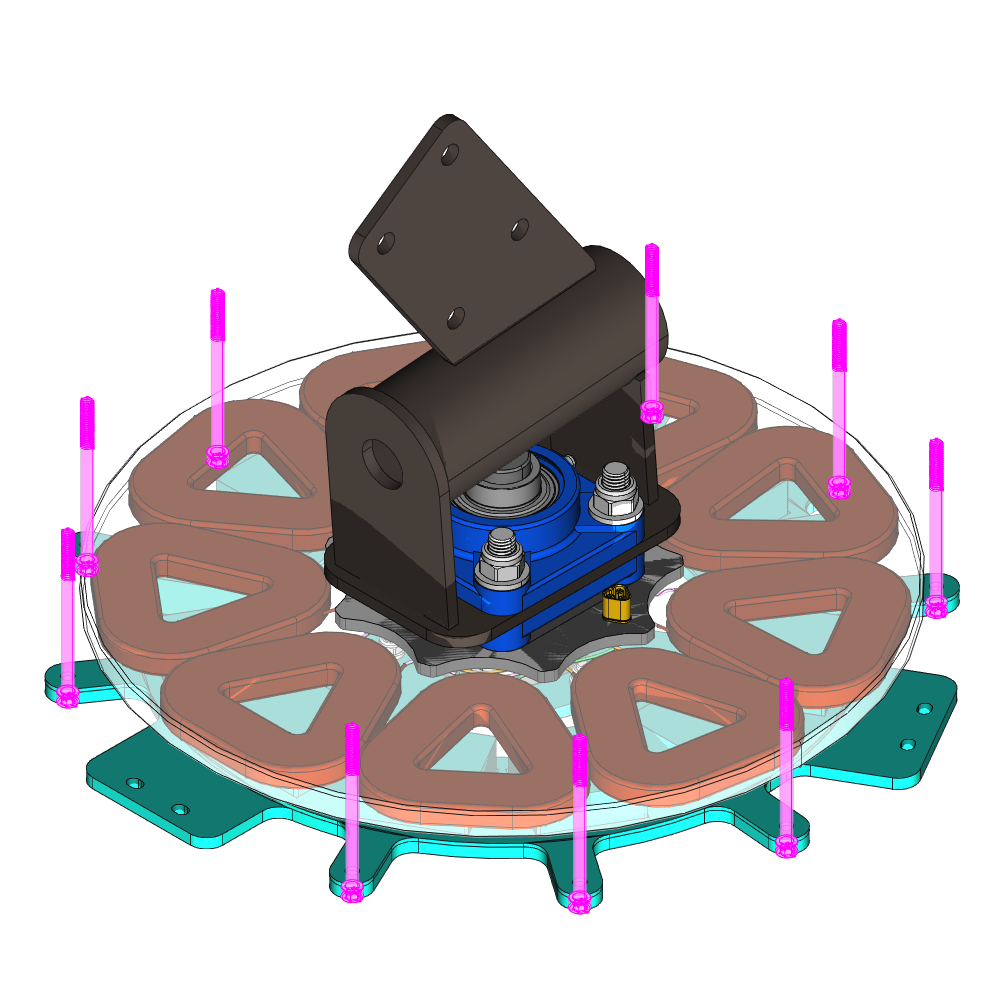

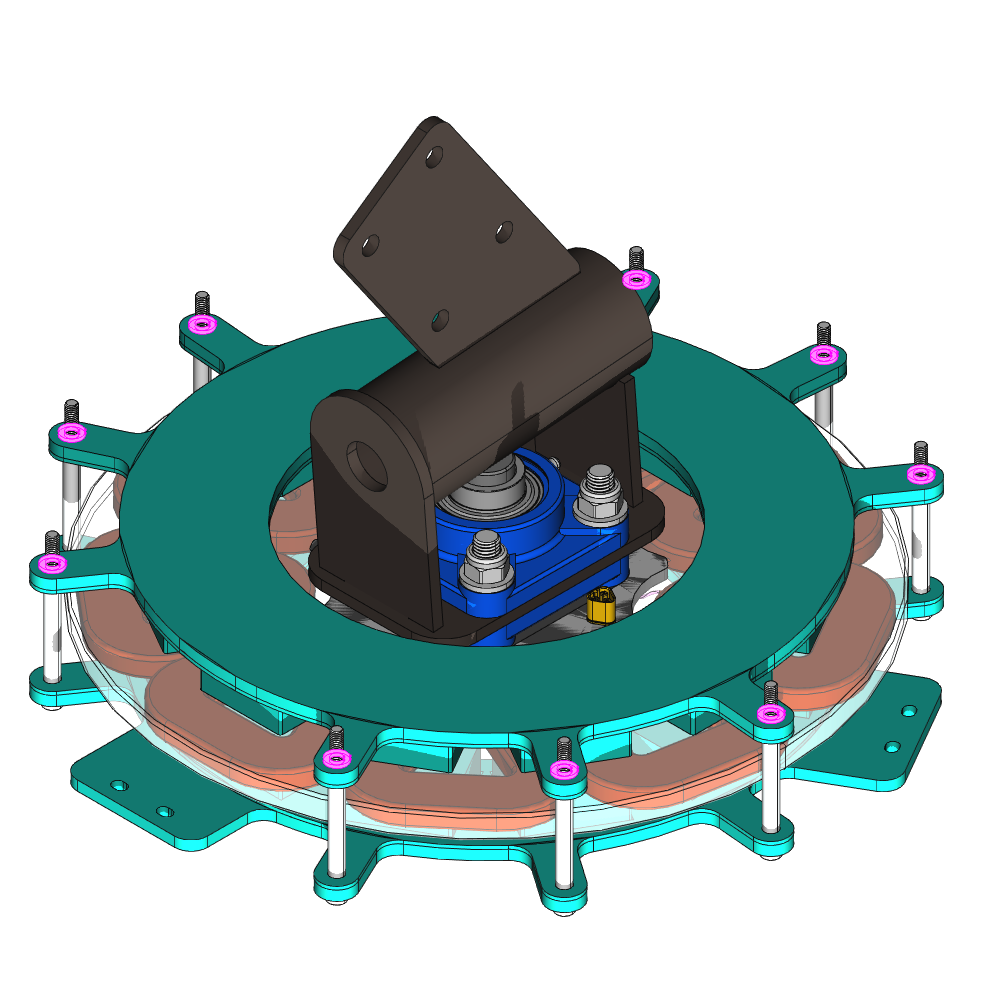

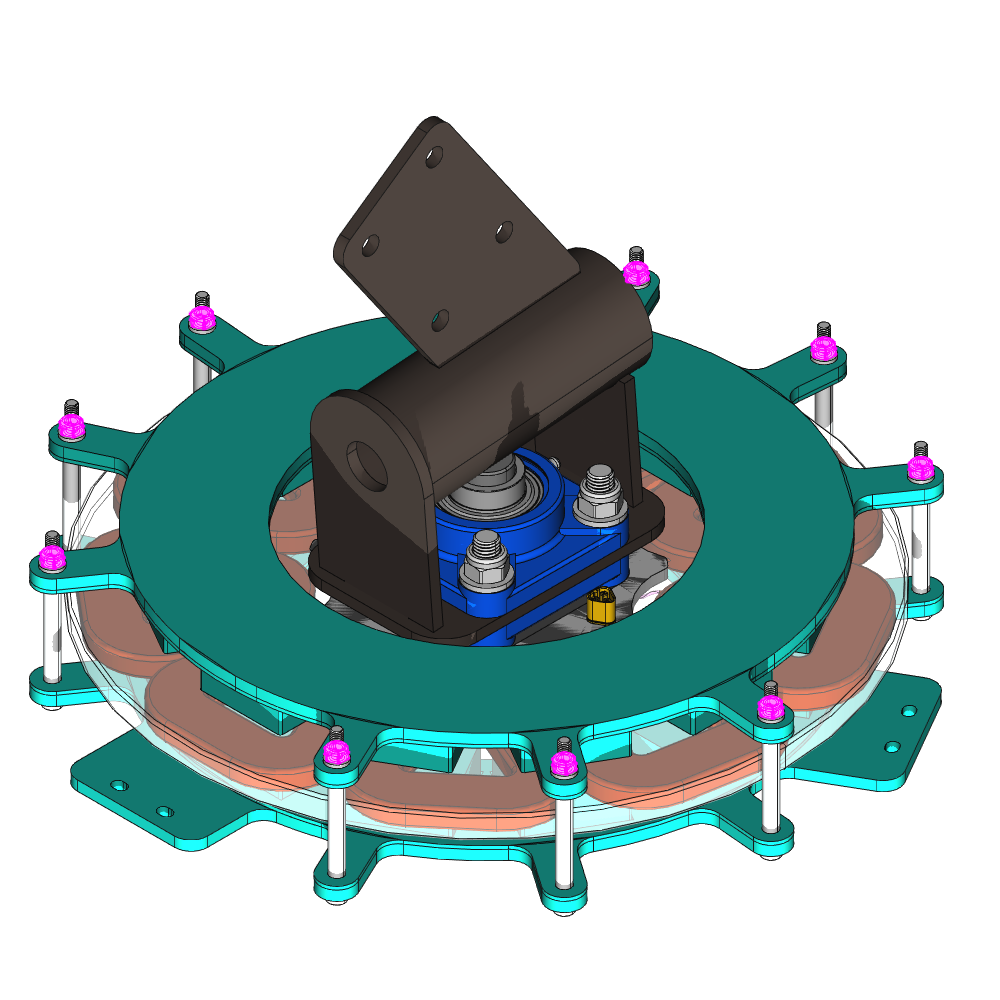

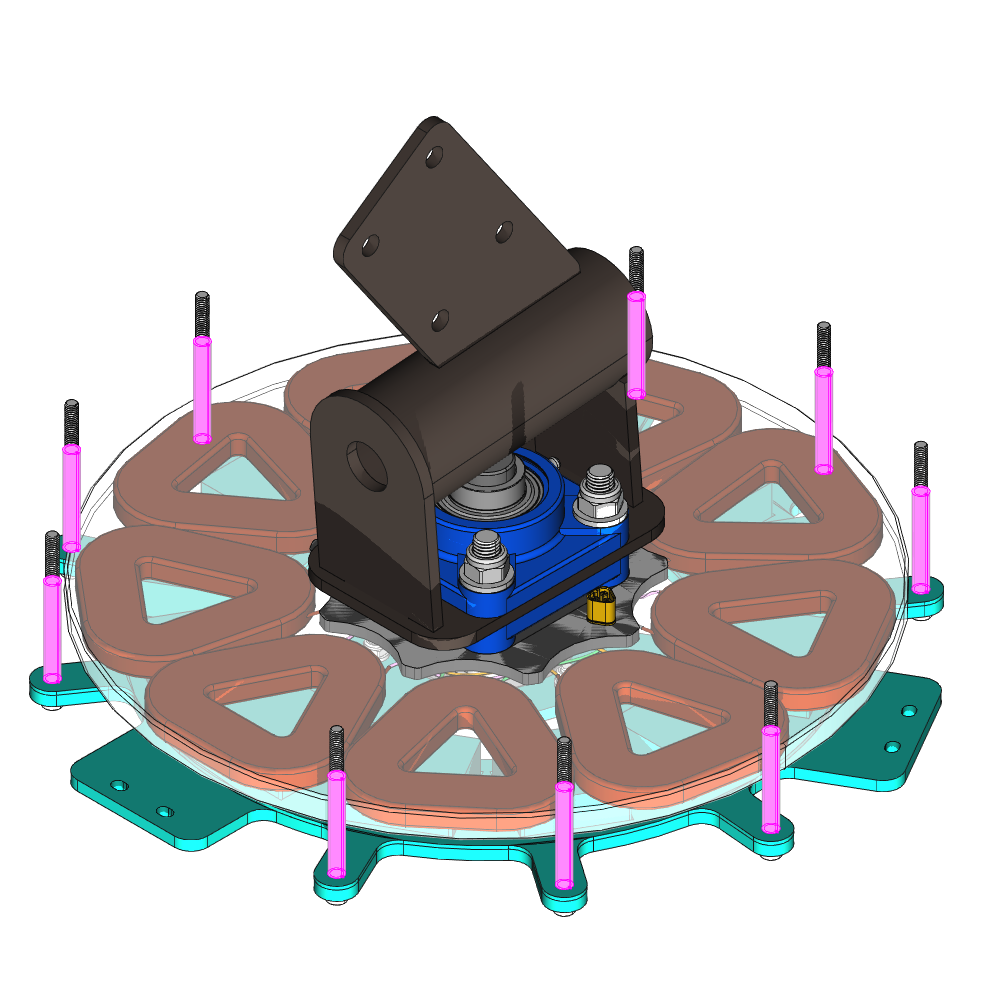

3.Altnator Rotor

We start by preparing and mounting the painted Upwind Magnet Disk.

Place the Taper Bush Hub

Mount on the Taper Bush Hub

6 x M6x25-Screw

6 x M6x25-Washer

Place the Taper Bush

Loosly tighten the Taper Bush Set Screw

Place the Upwind Magnet Disk onto the Shaft

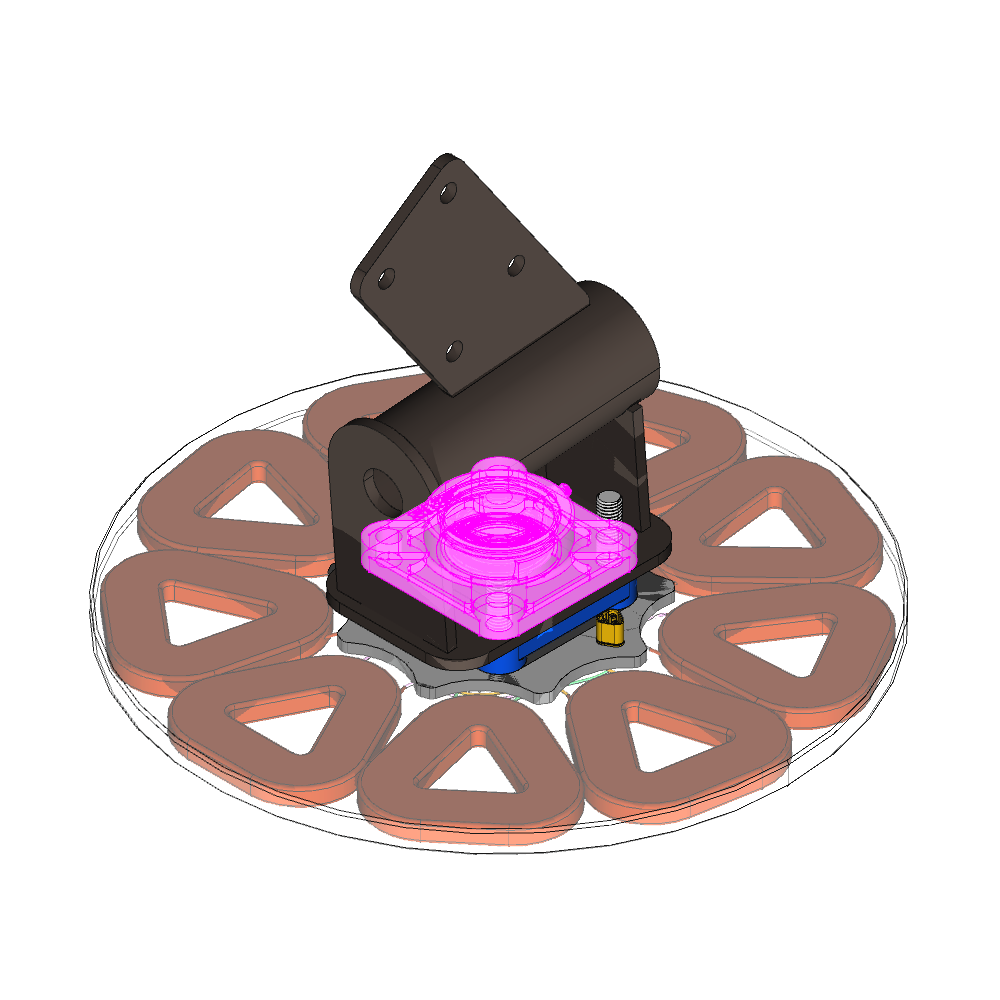

Tighten the Taper Bush Setscrews

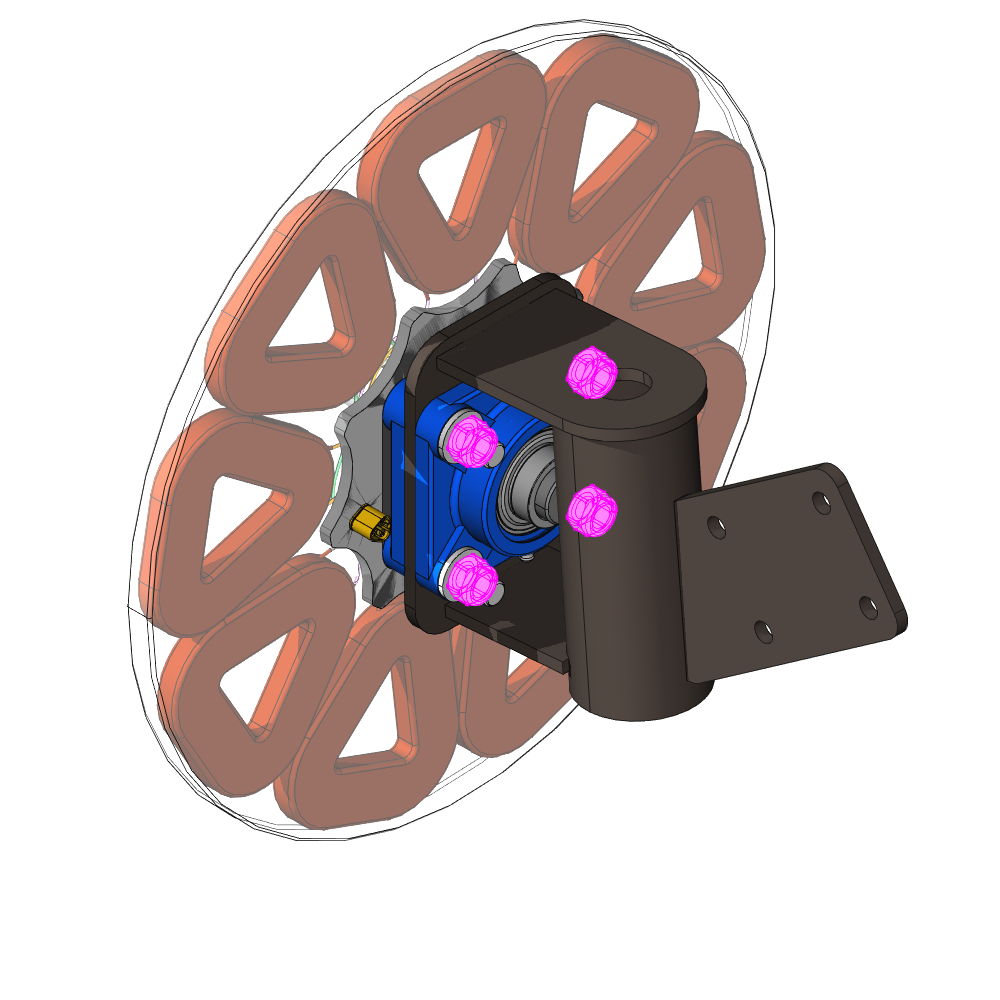

Add the Disk Fasteners

To do this, turn the assembly upside down and insert the screws from underneath.

9x M6x85-Screw Stainless Steel

Place a few pieces of wood underneath to hold the screws in place.

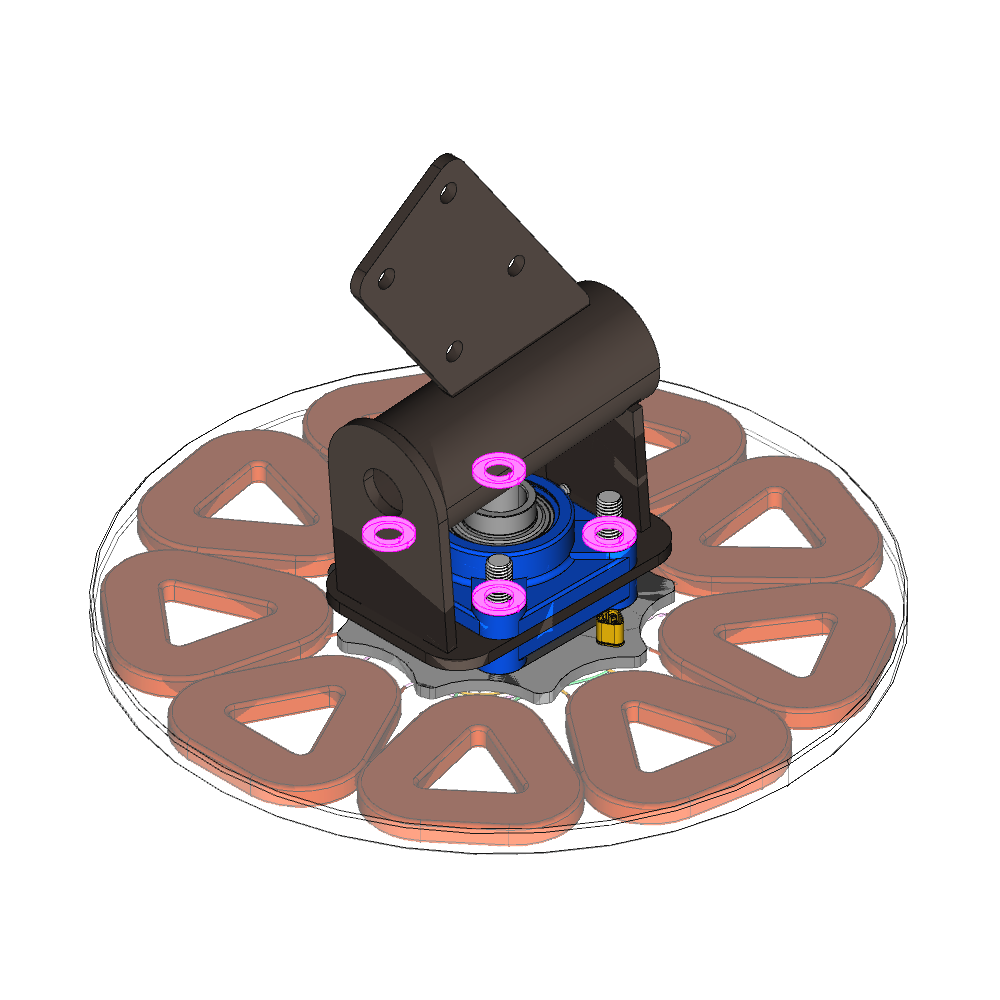

Add the Spacer Sleeves

9x Stainless steel sleeves 8x6x1 mm (up to M6), 50mm Length

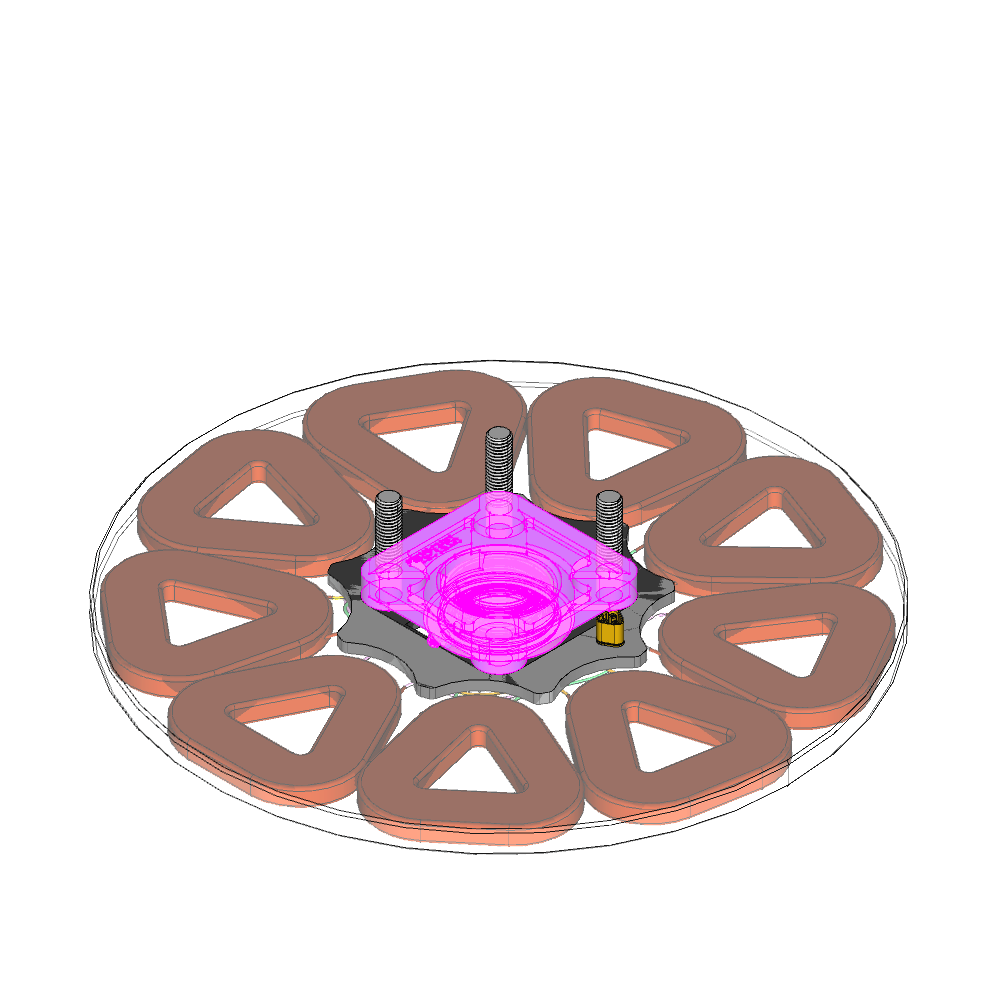

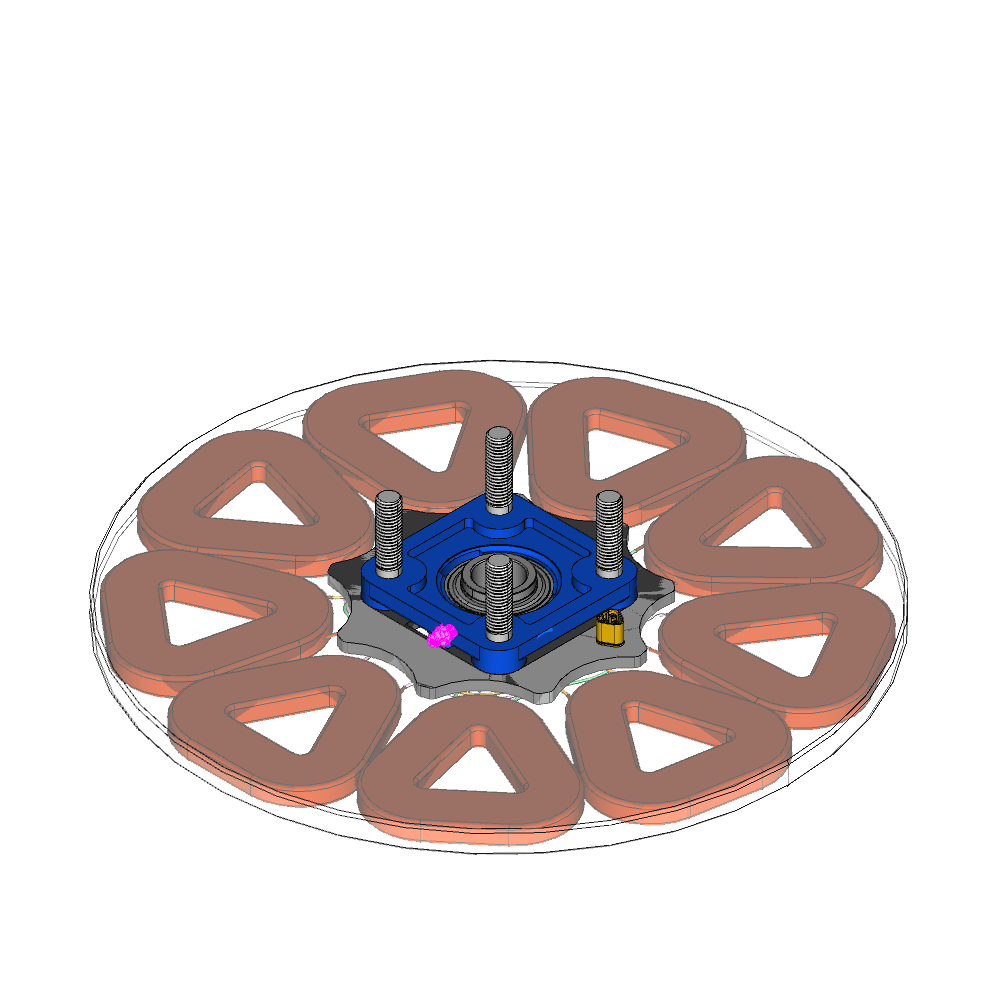

Add Downwind Magnet Disk

Important: Place some wood pices between the stator and the rotor to prevent damage due to the strong magnetic forces!

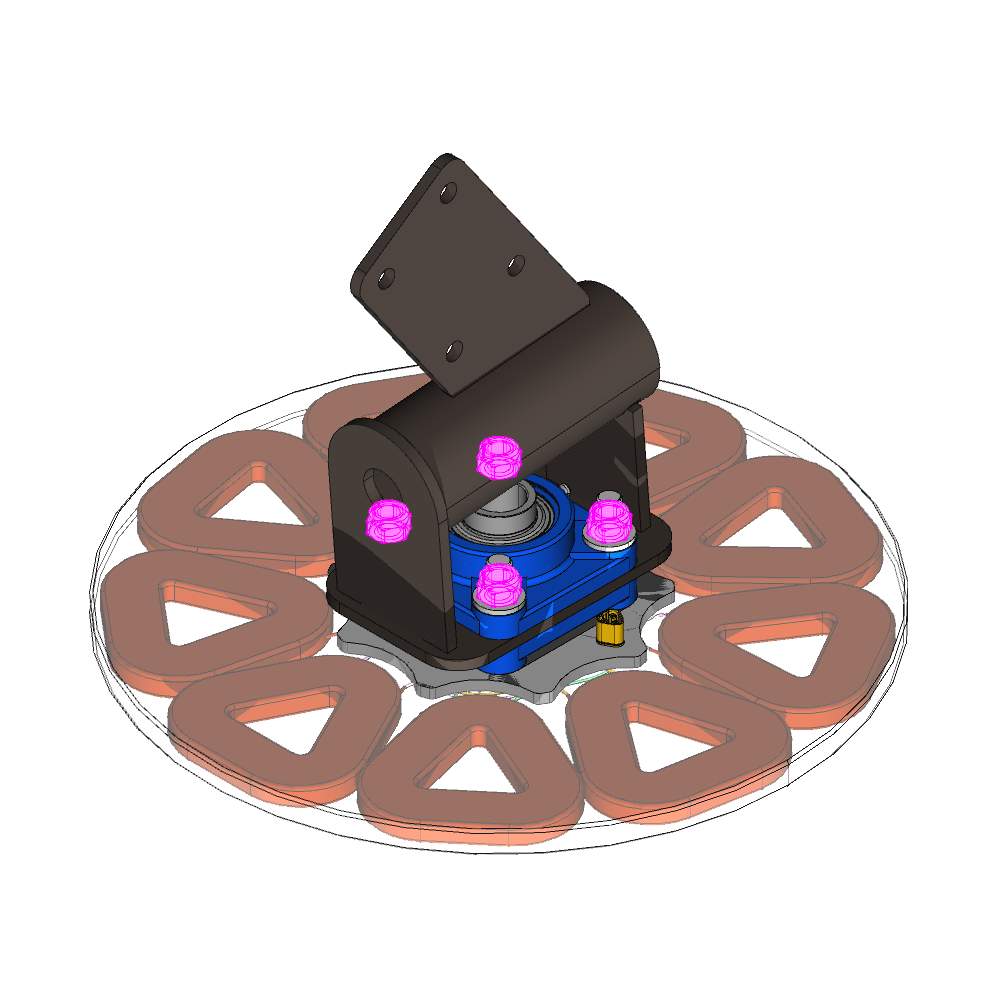

Tighten the Alternator Stator

9x M6-Washer

9x M6-Nut

Measure the airgap

Measure the airgap -> if to big, disassemble take our washers, add shim washers (DIN 988) to adjust -> iterate

Alternator is ready to be used

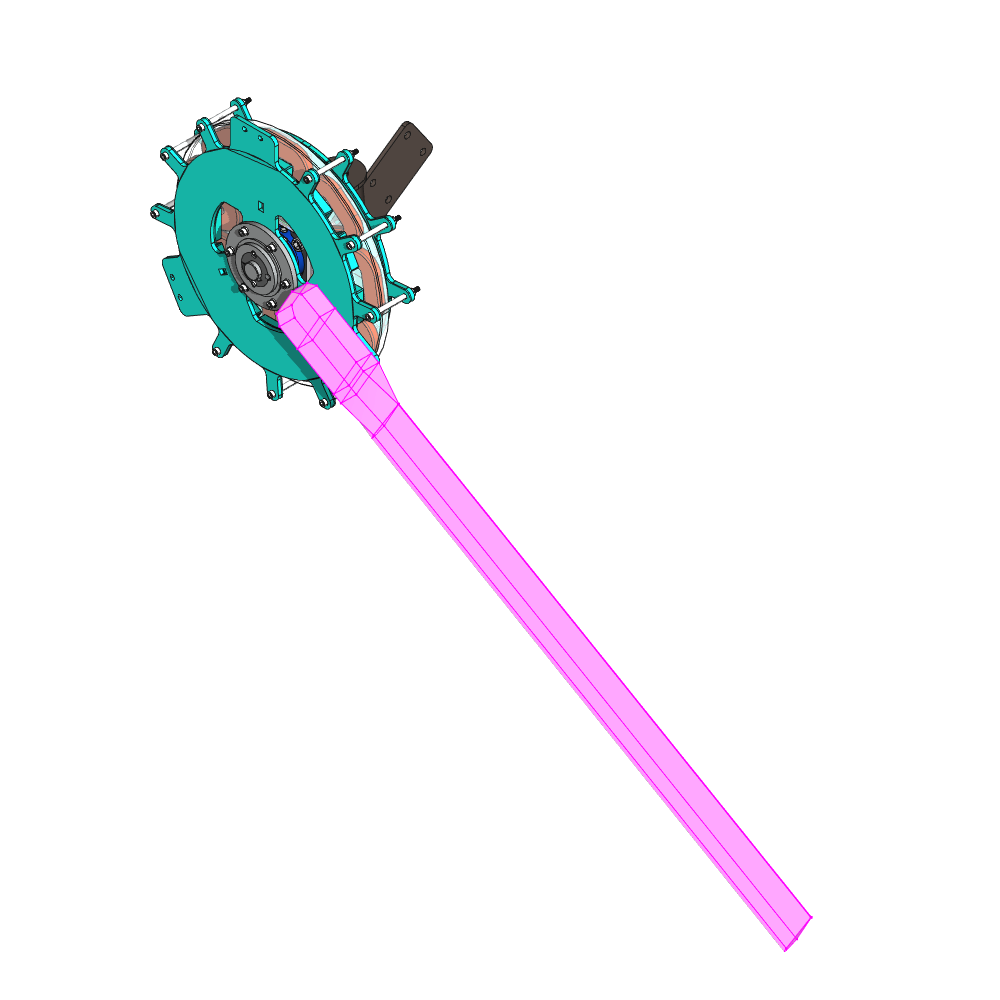

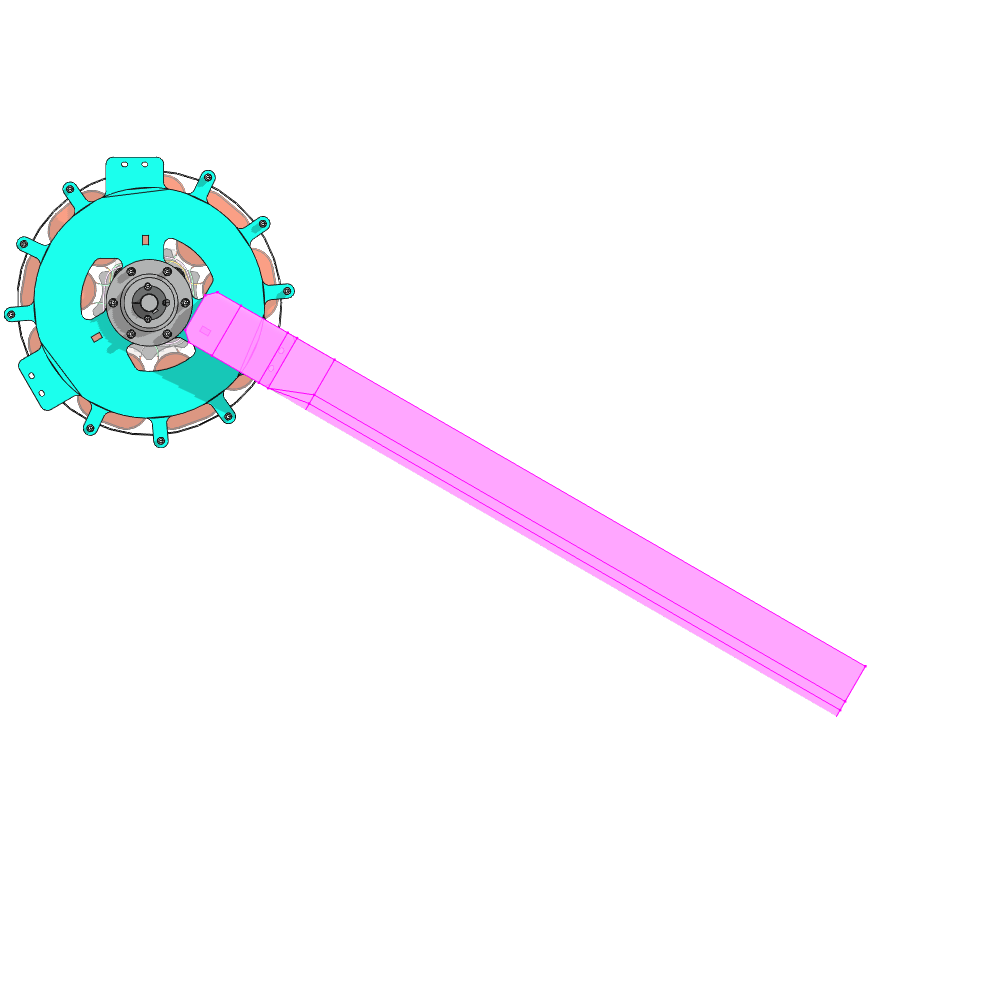

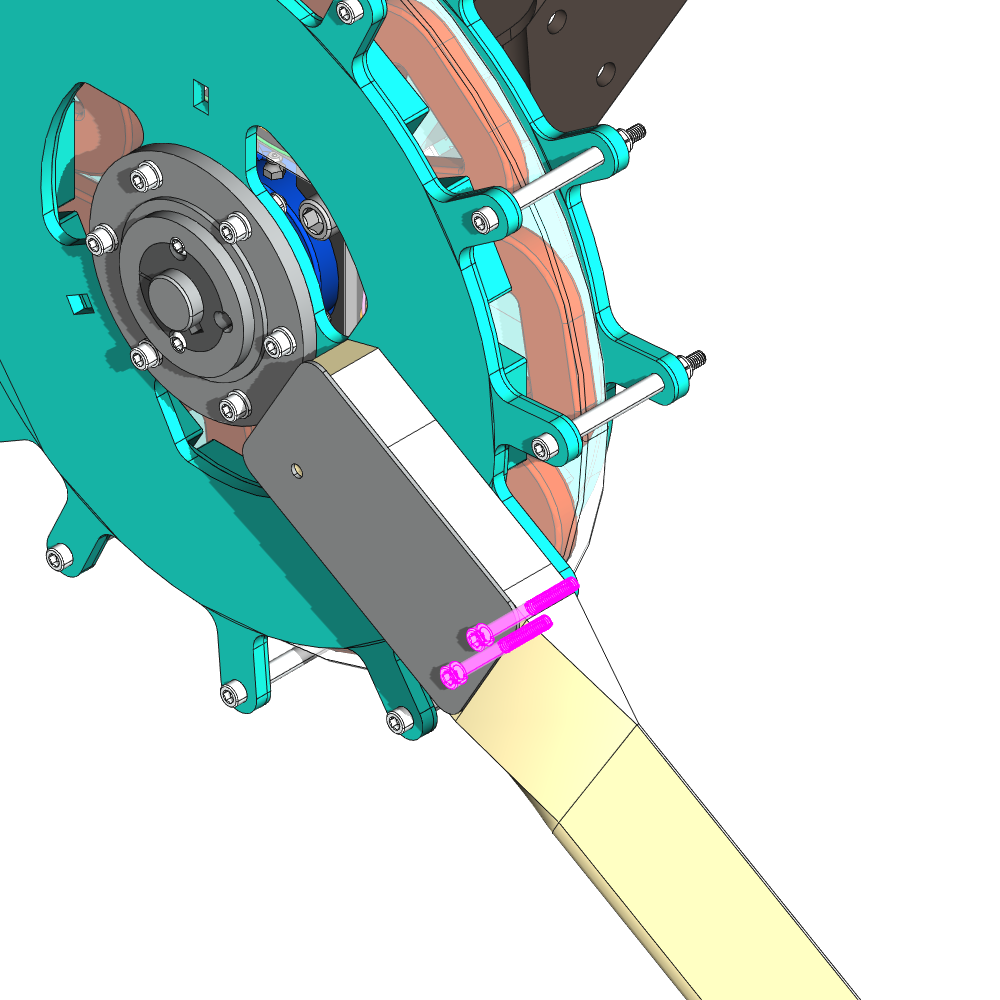

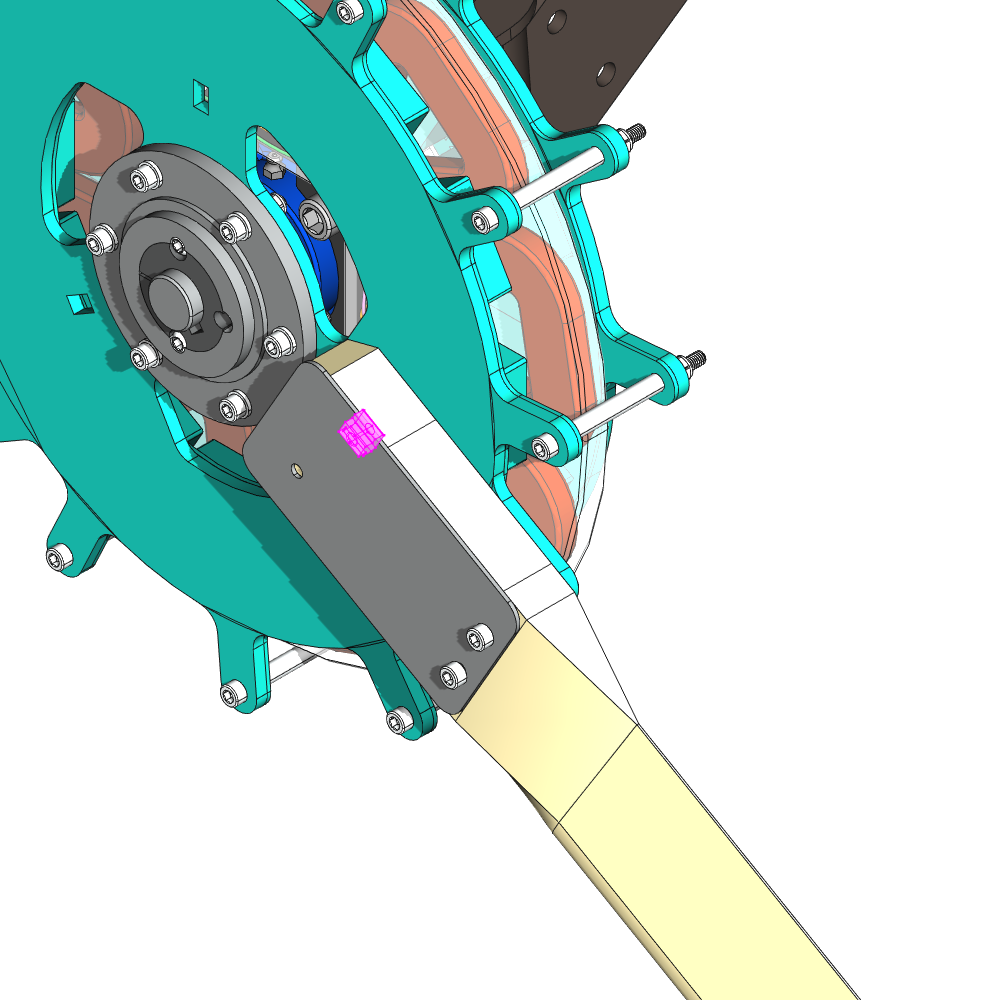

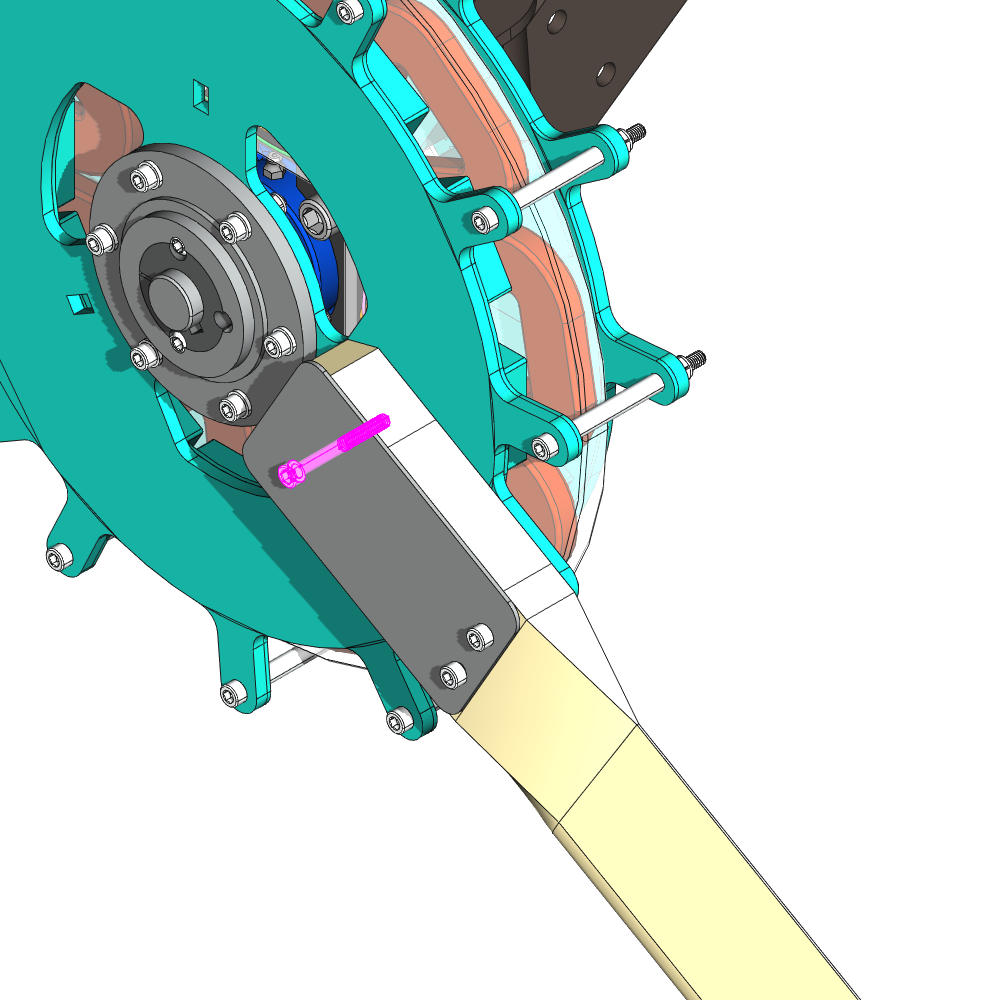

4.Rotor

Place the first Rotor Blade

Also place the Rotor Front Mounting Plate

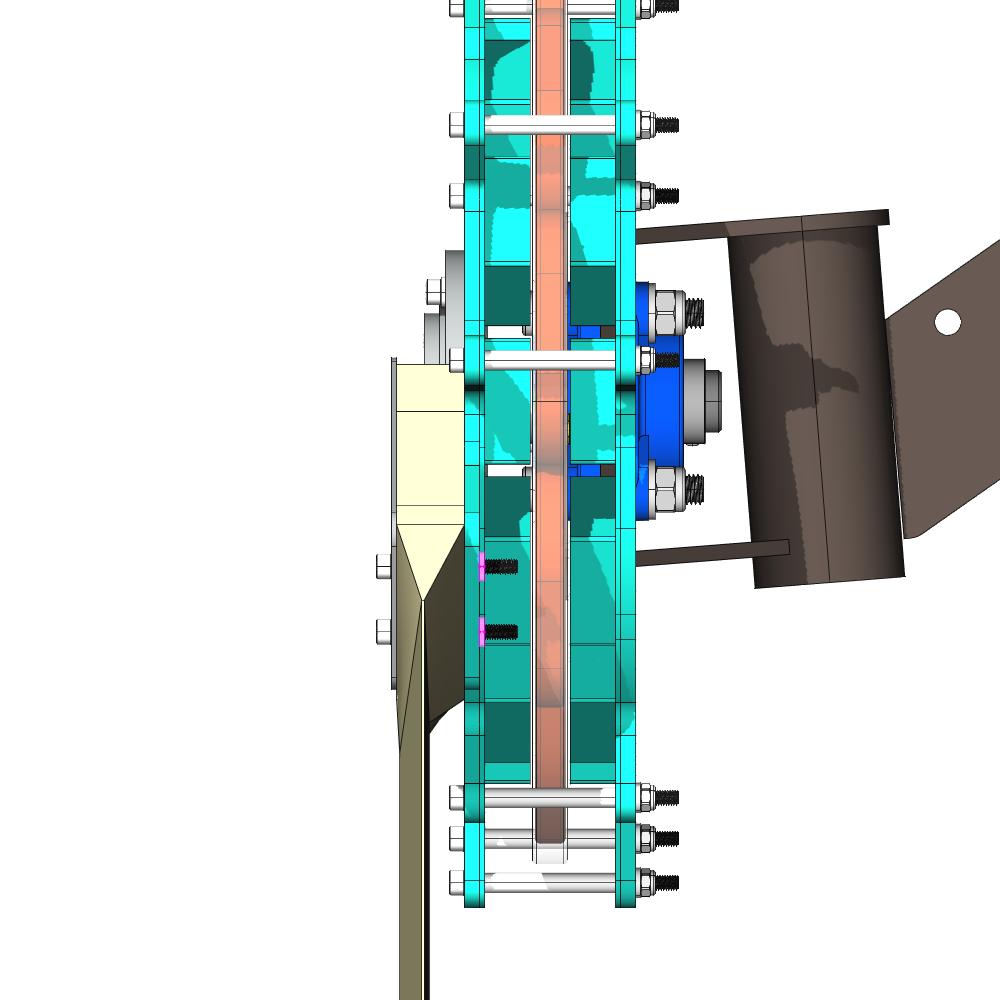

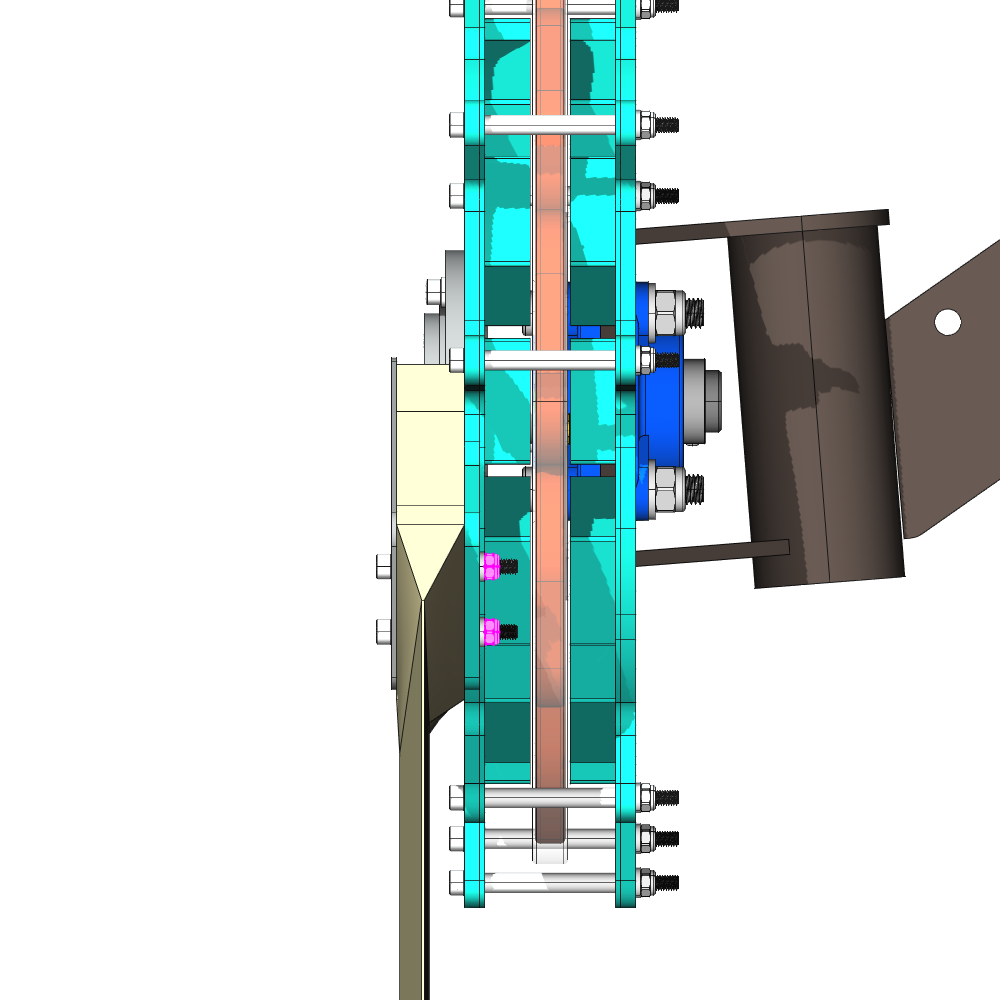

Attach the Rotor Blade with the Rotor Blade Fasteners

The the inner screw will have a special nut, the Rotor Blade Fastener Slot Nut. The slot nut is placed in the rectangular hole.

The the inner screw will have a special nut, the Rotor Blade Fastener Slot Nut. The slot nut is placed in the rectangular hole.

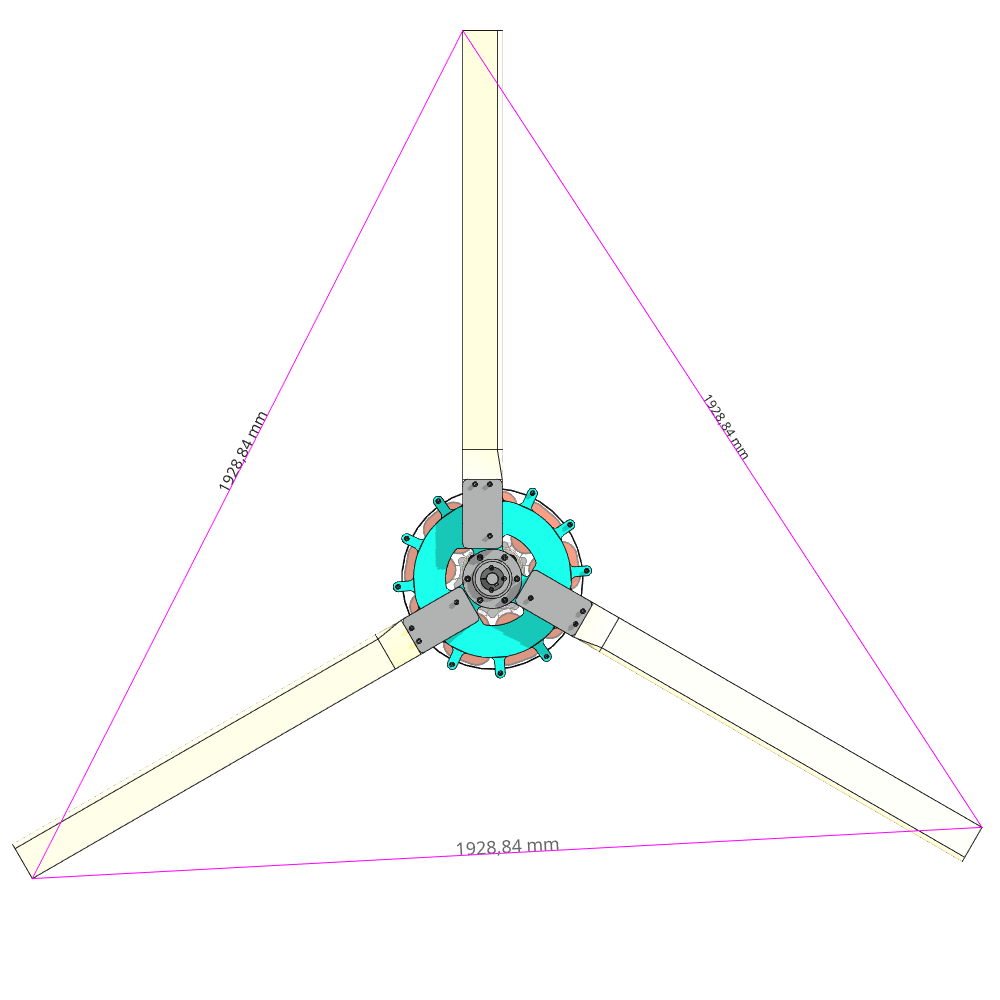

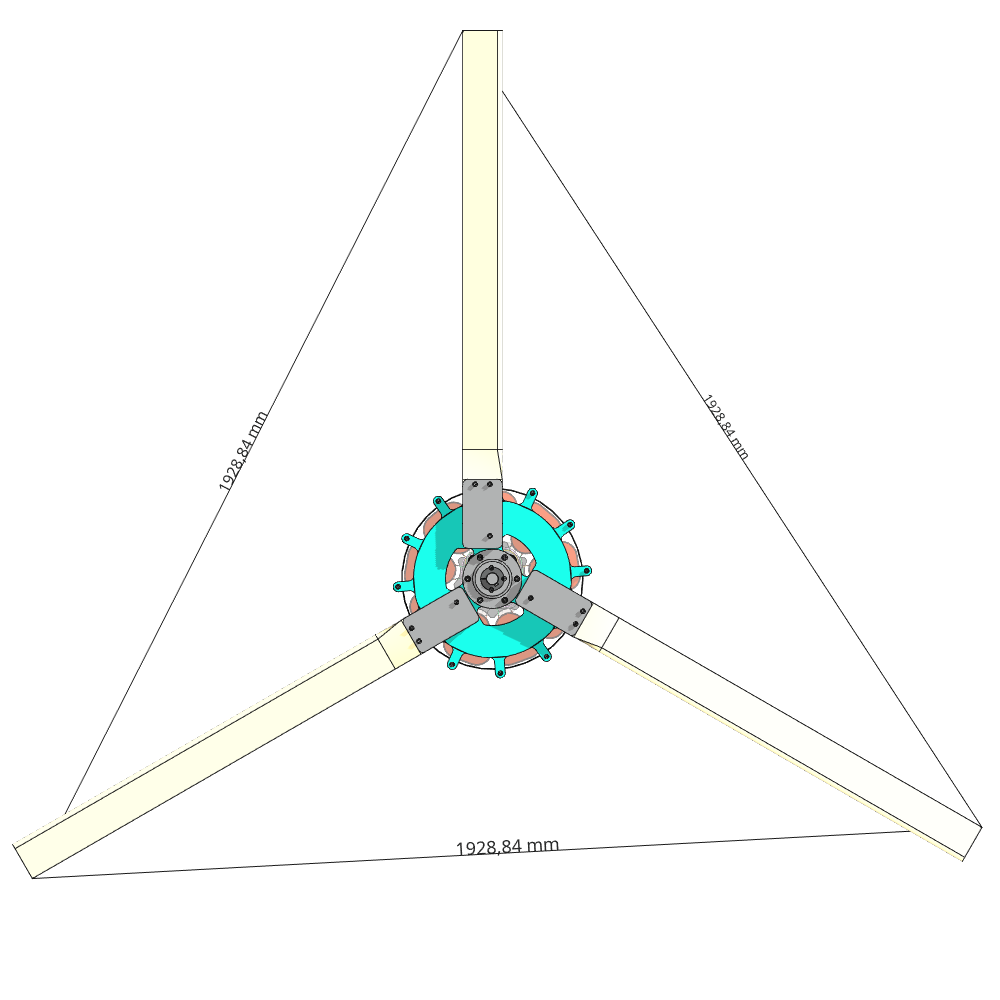

All Rotor Blades assembled

Repeat the last steps with the two other blades

Measure and center the blades

Measure and write down the distance one tip of the blade to another. After the first measurement, adjust the blades by unscrewing the outer blade fasteners, move the blade and re-tighten the fasteners. Repeat this process until you have a satisfying result.

| Distance | 1. Measurement | 2. Mesurement | 3. Measurement |

|---|---|---|---|

| A - B | X cm | X cm | X cm |

| B - C | X cm | X cm | X cm |

| C - A | X cm | X cm | X cm |

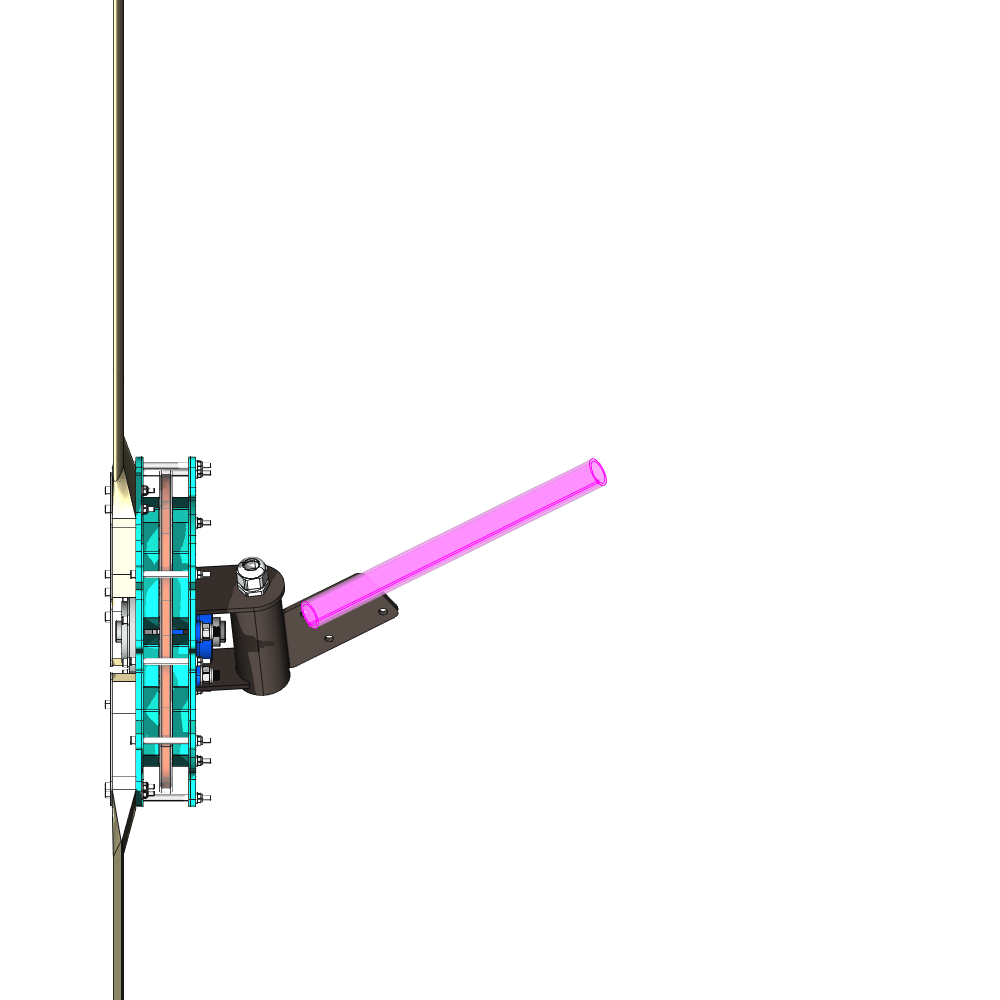

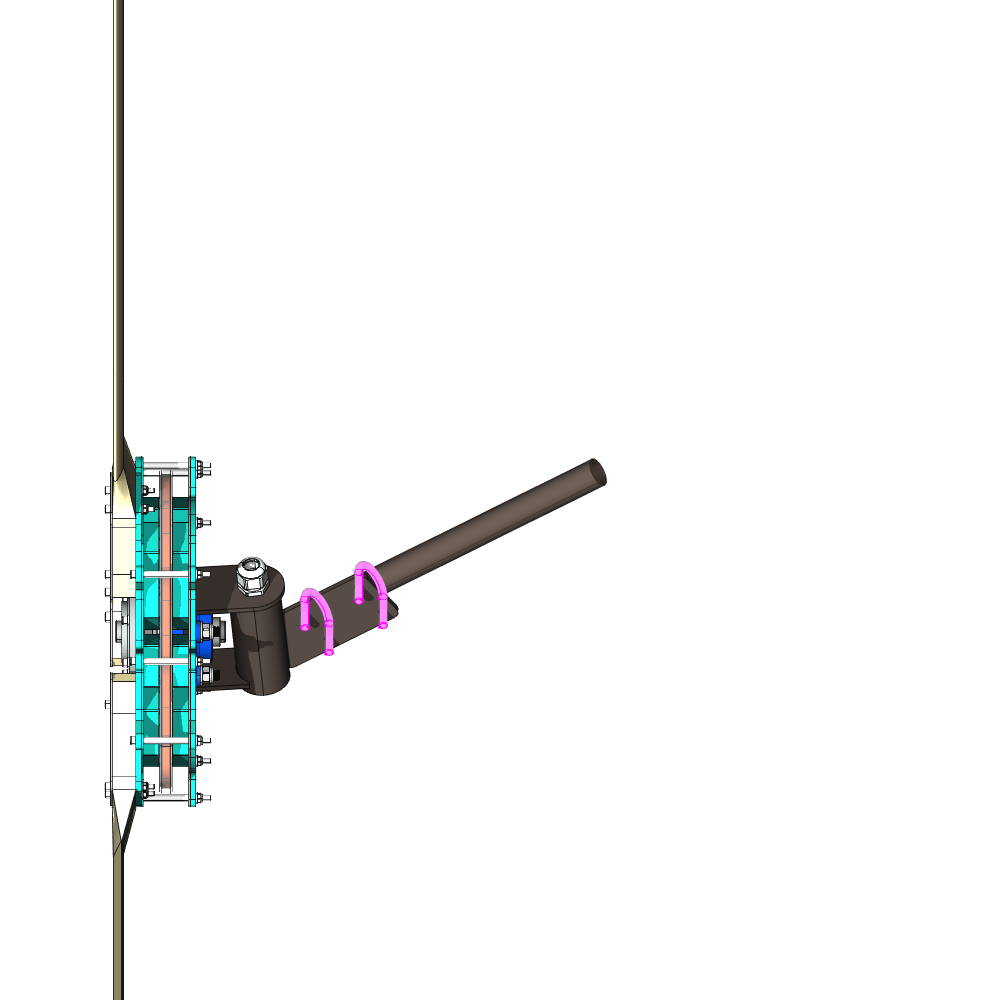

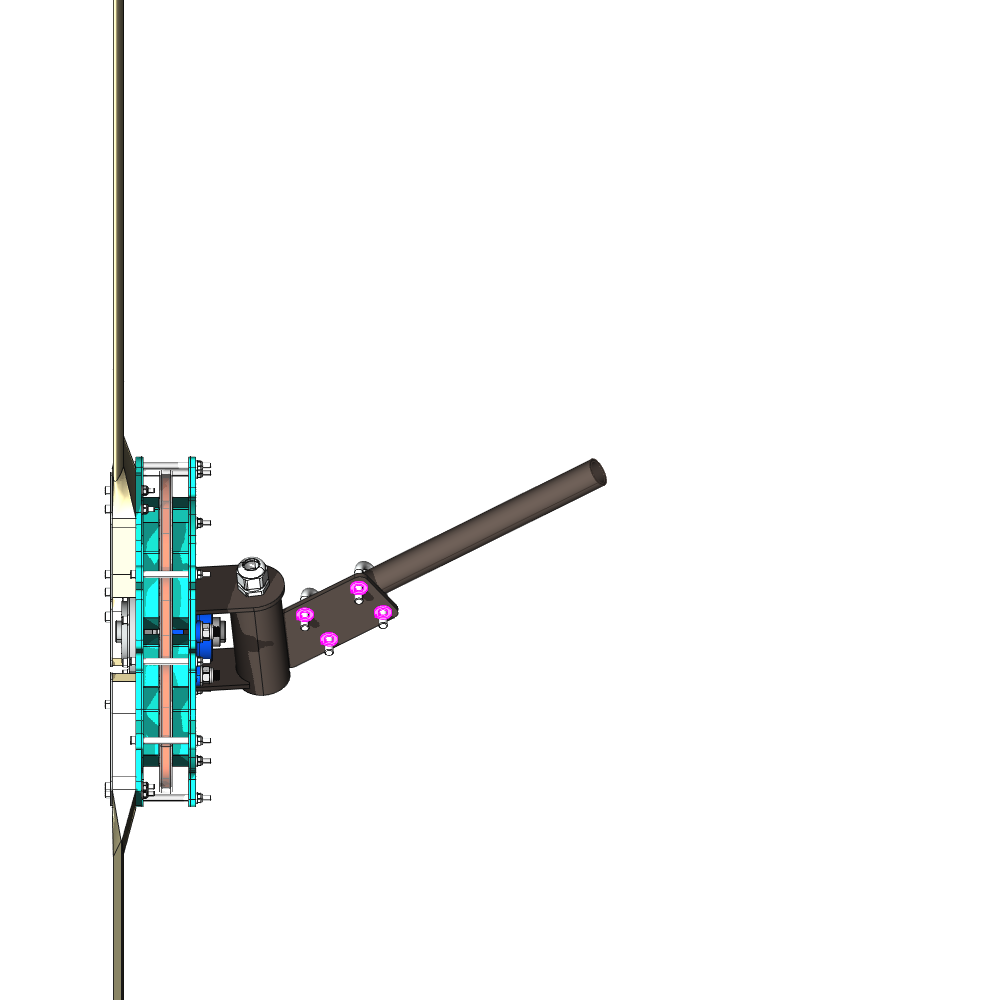

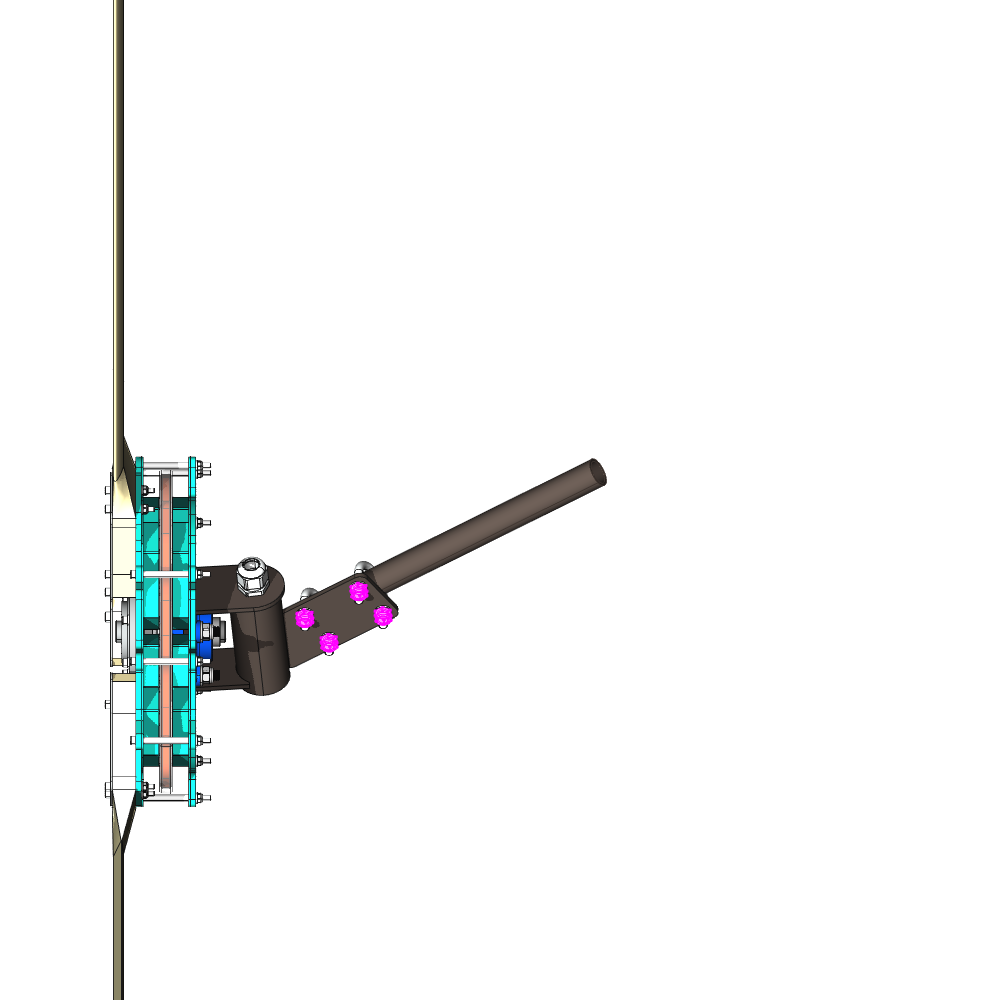

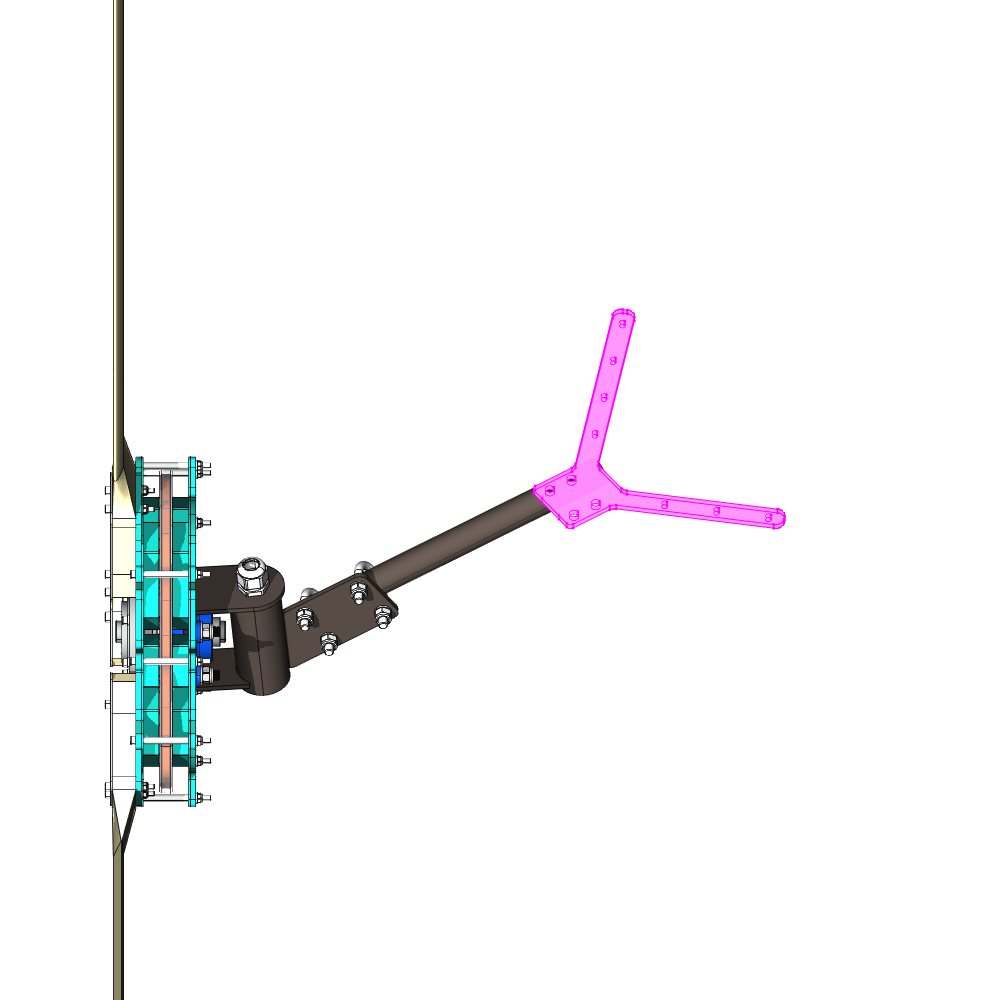

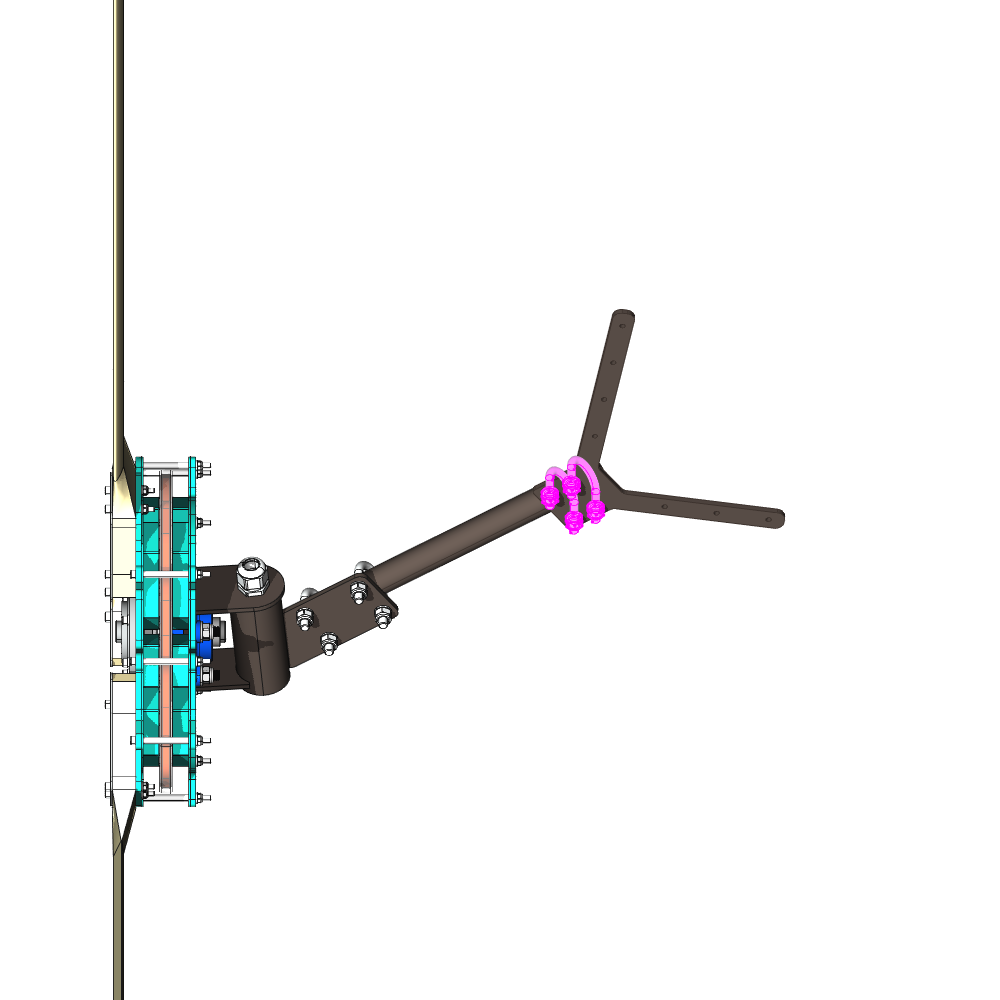

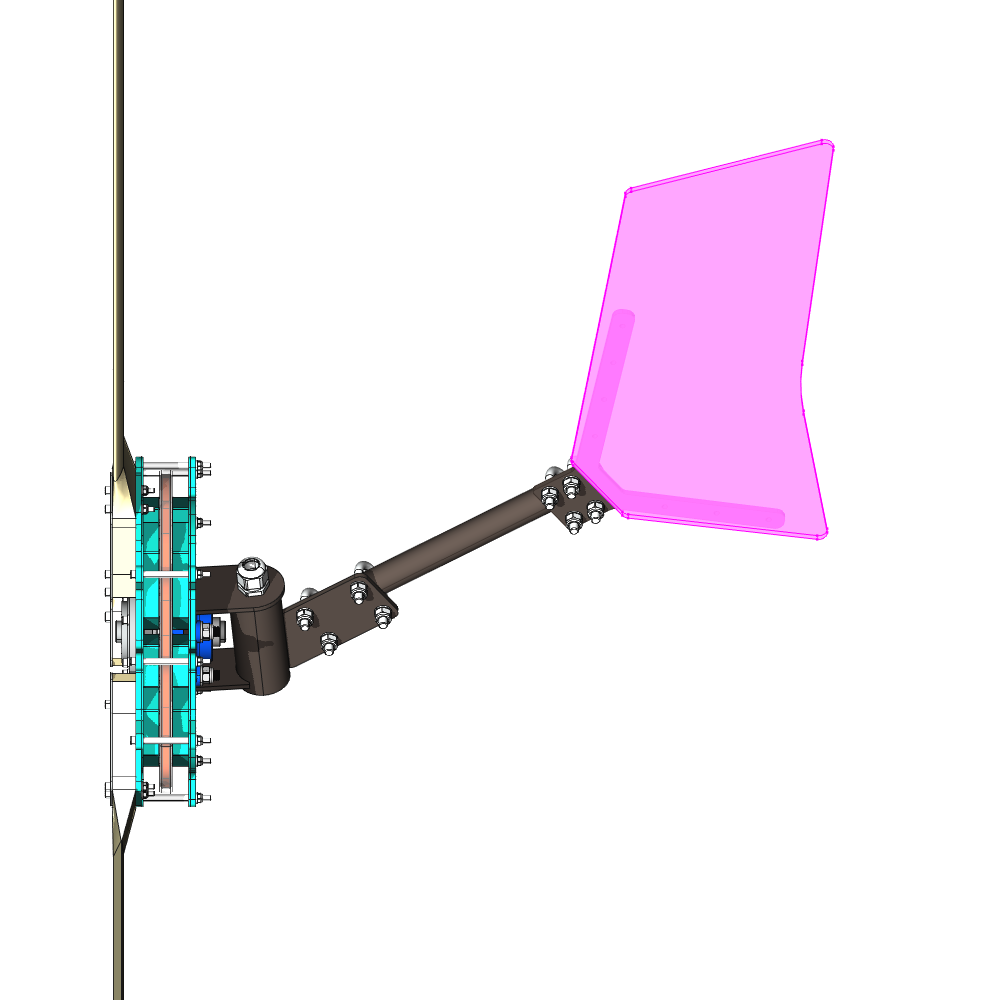

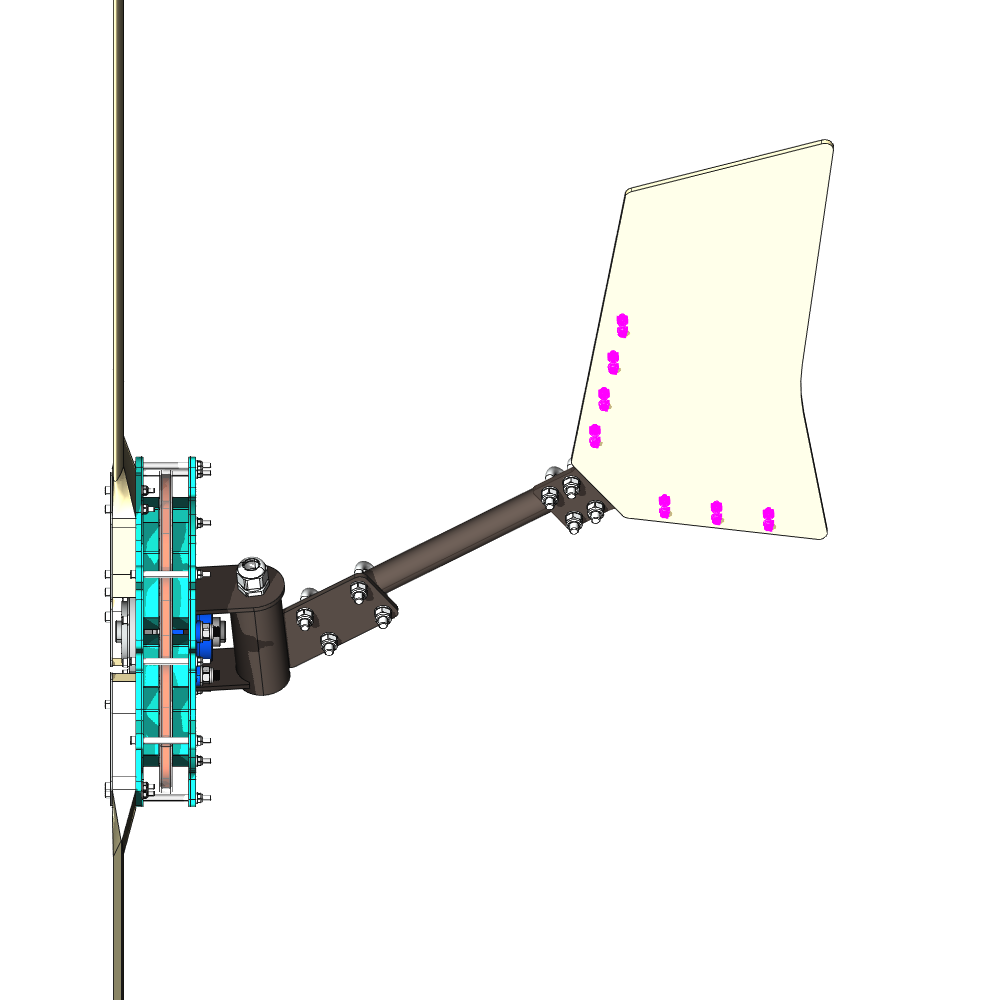

5.Windvane

Place the Yaw Pipe

Attach the Yaw Pipe with the U Bolt Clamp

Attach Vane Mounting

Place the Vane Mounting upright and attach it the the U Bolt Clamps

Place and Mount the Vane

Use the Vane Fastener to attach the Vane

Cable

Attach the Cable Gland

Install the Cable

TODO